Scientists are curious and want to know more about our surroundings. Image If it seems very small, the biological stuff, be sure to include the study of the particles, cells, the basic building blocks of life, so you can figure out how it all works. To study these tiny things, though, scientists need special tools with which they can separate and analyze the samples they gather. Well, one of the main tools they use is a Jinke Optical centrifuge cuvette!

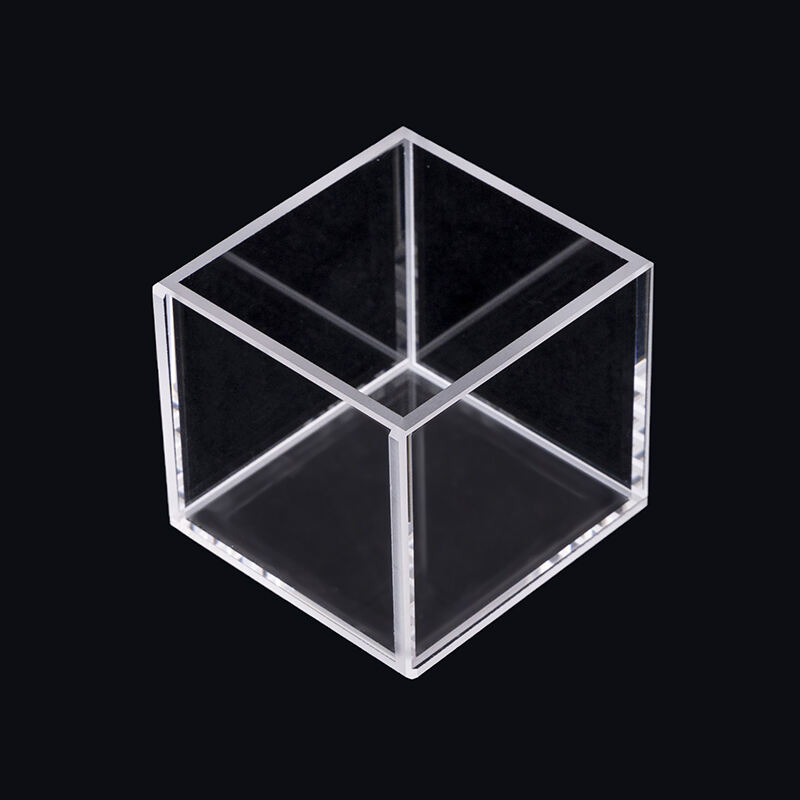

A centrifuge cuvette is a special type of container that is used for holding biological samples, such as blood, saliva, or other small cells. This container is integrated into a device called a centrifuge. The centrifuge has the special task of spinning the samples very quickly! After the machine spins, the heavier parts of the sample sink to the bottom of the glass cuvette, and the lighter parts float to the top. The process results in two distinct layers in the cuvette. Then scientists can examine these layers closely, and learn more about what is in the sample, and how it works.

Sciences working on samples will want to analyze them rapidly and accurately to achieve top results. That is where the centrifuge cuvette shines! Because of the centrifuge's high-speed whirling, samples can be swiftly separated into their respective layers. This speed saves time for the scientists, enabling them to move on to the next stages of their findings without any delay.

But speed isn’t the only thing scientists desire. They must also be assured that the results they receive are accurate and trustworthy. With a Jinke Optical centrifuge cuvette glass, scientists can be confident they are getting accurate results every time they utilize it. The rotation is guided, which enables even spinning of the samples and is a critical aspect to separate the layers uniformly. This consistency enables scientists to compare their findings to those of other experiments, verifying that their results are correct and reliable.

Not only is the centrifuge cuvette a great tool, it is an innovative addition to the technology! The leaps taken in its development have enabled scientists to run operations and run investigations that had been impossible before. As an example, the centrifuge cuvette can separate very small particles, such as DNA, with a high degree of separation efficiency. This capability allows researchers to examine these vital components of life in far greater detail, potentially helping make exciting new discoveries.

When scientists commit their funds that they are spending on scientific equipment, they need to know the equipment is going to last a long time and is going to work well over time. This is where the Jinke Optical centrifuge plastic cuvette is meticulously crafted for peak performance and structural integrity. So, this is built from sturdy components, and can tolerate the repeated forces of spinning samples. So even a decade later, it's still able to perform efficiently, even used all day long in busy labs.

Called centrifuge cuvettes, their applications include many areas in the medical and scientific fields. Doctors can use it to separate components of a patient’s blood. This allows them to better diagnose diseases and find more effective treatments. The centrifuge cuvette can also be used by scientists to examine interactions between various materials. Which can contribute to further discoveries in fields such as drug development and other scientific discoveries. The cuvette uv spectrophotometer could be serve you in endless possibilities!

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.