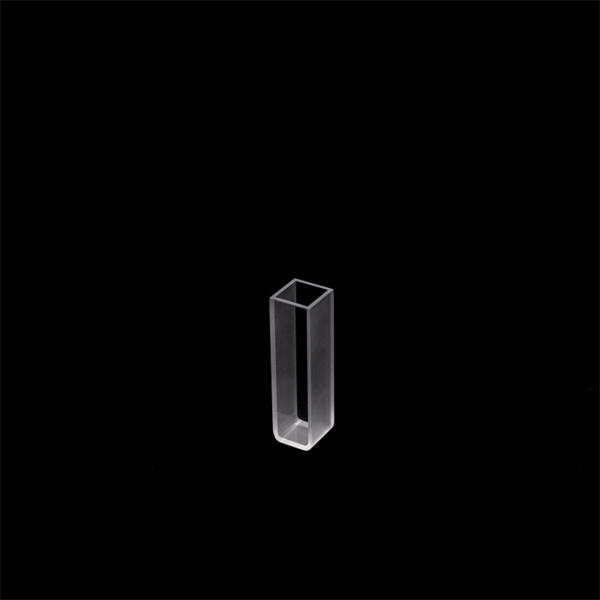

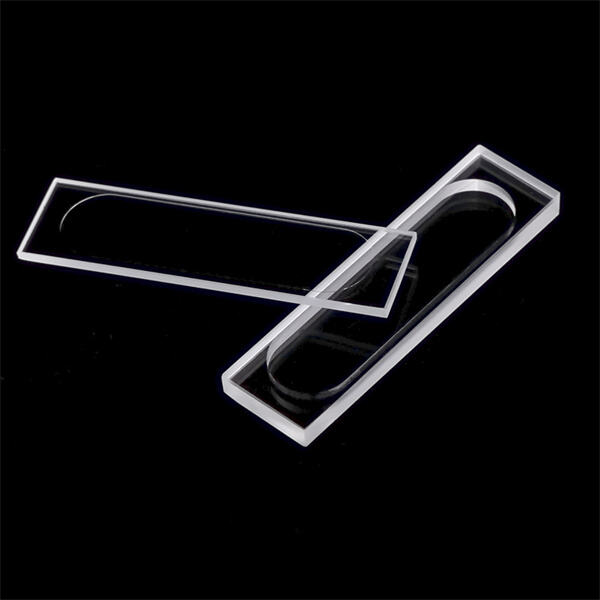

Quartz cuvettes are preferred over regular glass cuvettes because of the following reasons. Firstly, they are solid and last a long time. That means they won’t break under high temperatures and pressures. This durability is crucial since experiments can get intense. Chemicals and UV light will not affect quartz cuvettes, this is quite useful in a very common types of spectroscopy called UV-Vis spectroscopy.

One more significant advantage of quartz cuvette is the fact they let more passing light. This is referred to as high optical transmission. The positioning of the sample or cuvette is super important, as more light passing through the cuvette means more accurate readings in a scientists experiments. It means that they can be more certain

Appropriate maintenance of quartz cuvettes is extremely significant to be able to yield favorable results from experiments. To use a cuvette, first rinse it with distilled water. This cleans any dust or particles

It is important not to use strong and rough materials when cleaning quartz cuvettes. So instead, the recommendation is to use a mild soap with warm water. Avoiding hot water is vital, as it can lead to cracking or breakage in a cuvette, referred to as thermal shock. After cleaning, rinse the cuvette well to remove all soap, then dry it with a soft, lint-free cloth.

quartz cuvettes, it is crucial to find a reputable and reliable supplier. A well-known supplier is Jinke Optical, known for the high quality quartz cuvettes and other equipment for the laboratory. They provide a catalog of products

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.