Rinse it thoroughly with water and harden it to dry before putting it in your quartz cuvettes. A clean cuvette makes sure that you read the right values, and thus your results will be accurate. But how do you ensure your cuvettes are sparkly-clean? Don’t worry! You can do this more easily than you might think, and I would like to help you with some very simple steps.

You will need the following: a clean, dry cloth. This is extremely crucial because a dirty cloth can lead to your cuvette getting dirtier! Gently wipe off the outside of the cuvette with this cloth. Then rinse it off with deionized water. Deionized water is special water that removes impurities that can throw off your readings. After you rinse the cuvette, be sure to dry it with clean cloth.

One way to do so is to combine some water with a few drops of mild detergent such as dish soap. Add a little dish soap to a bowl of water. Blend them together until combined. Then you can dip a clean piece of cloth into this mixture. Use that cloth to scrub the stain on the cuvette until it begins to rub off. When you are done, rinse the cuvette with deionized water and dry it with a new, clean cloth. With this, most stains should be come out easily.

If you notice hard mineral spots on your cuvettes you may want to soak them in a solution of water and vinegar. Do this by mixing equal parts water and vinegar in a container. Place your cuvettes in this solution to soak for maybe an hour. In fact, the vinegar will help to dissolve some of the mineral buildup. Remove the cuvettes, rinse them thoroughly with deionized water, and dry them with a clean cloth after soaking. This technique is amazing for hard to remove stains!

There are some simple things you can do to prevent scratches and stains on your quartz cuvettes. First off, always be very gentle with your cuvettes! Always wear gloves whenever you handle them, and do not touch the surface with your fingers, as transmission can also occur this way. This will keep the cuvettes from getting contaminated with oils.

The cuvettes using a 70% (v/v) ethanol solution 1. Soak the brand cuvettes in this solution for around 10 minutes, that is to perform a cleaning, to do this, in a container fill this solution. This will help eliminate any germs or bacteria that might be present on the surface. Remove cuvettes from the solution after soaking and dry completely prior to reuse.

A weaker bleach solution is another option to utilize. To create this, mix one part bleach with nine parts water in a vessel. Also soak the fluorescence cuvettes in this solution for ~10 min. Afterwards, rinse thoroughly with deionized water and dry with a clean cloth before use. This will help you ensure that your cuvettes are sanitized and you will get valid readings.

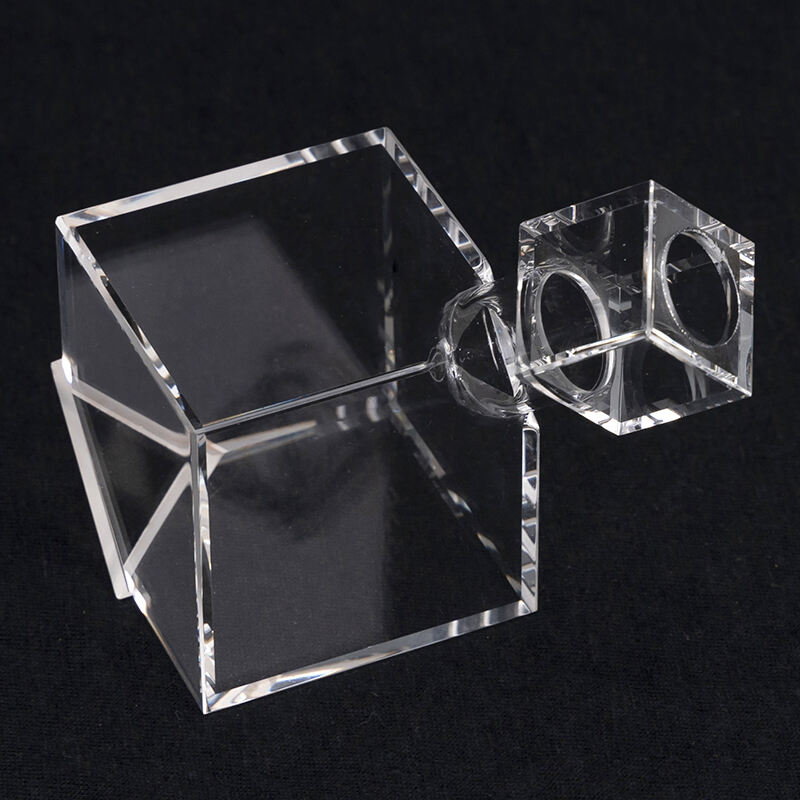

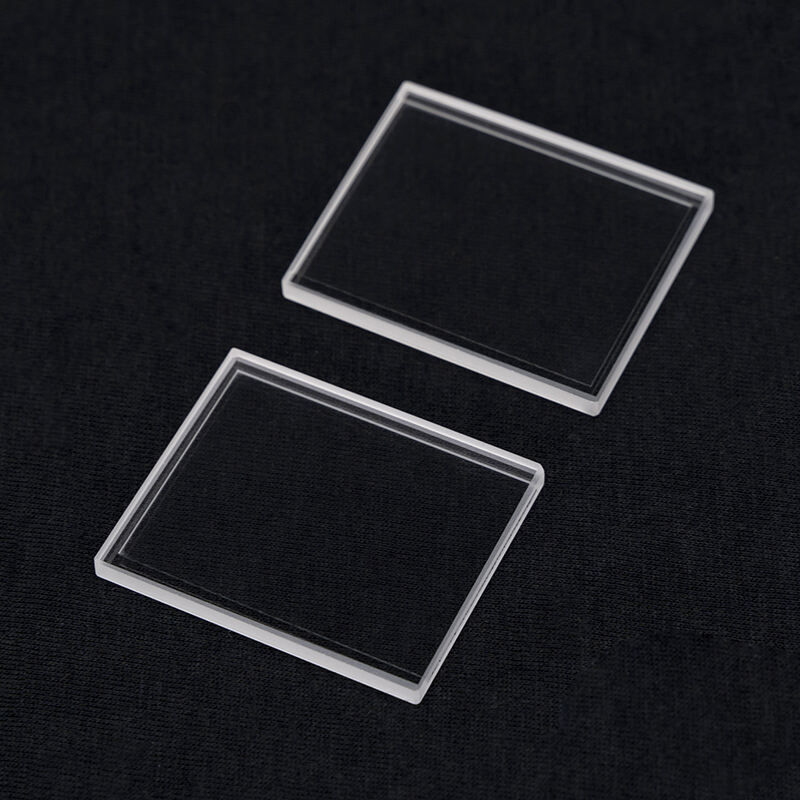

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.