Researchers performing experiments in the lab also need special tools to achieve the best and most accurate results. One of the most important tools that they are using is a cuvette cap. A cuvette cap is a small piece of plastic that fits over a cuvette. Now, what is a cuvette? A cuvette is a small vessel designed to hold a liquid sample that scientists wish to test or analyze. Cuvette caps are critically important when scientists need to measure light using an instrument called a spectrophotometer

So when scientists take a measurement with a spectrophotometer, they optical elements measuring how much light transmits through their sample. A crucial step towards attaining optimal readings involves shielding the sample from any external light that could disrupt the process. This is where the cuvette cap comes in useful. A cuvette cap prevents crevice scattering because it prevents light from entering or exiting the sample holder. This way they can guarantee that the measurement they take is right and that it is only displaying what is present in the sample itself. Until using cuvette cap, external light will be used in a way that alters its findings are incorrect and gives false conclusions.

Some samples scientists work with are very delicate things that can easily be altered by air, moisture, or other substances in the environment. When scientists need to analyze these sensitive kinds of samples, they must wear a cuvette cap to keep the sample safe from any external effects. This imaging flow cytometry cap forms a seal around the sample, so it can you know, be accurately tested without any outside environments influencing the importance of the sample. This protection is vital for obtaining accurate results from the experiments

Fifth, scientists need to make very accurate measurements in the laboratory to really ensure that everything in their experiments is true and trustworthy. A cuvette cap is instrumental in aiding this level of precision. This cap holds the cuvette firmly so that it does not spill or leak. When everything is properly sealed, then scientists can be sure that the measurements they take are accurate, as they do not waste any of the sample or risk tainting it. Precise measurement is critical for sound experimental work.

Then we came up with our solution: Cuvette caps that work with most standard cuvettes, making them a universal tool that anyone from scientists to kids can use to add a new dimension to their experiments. The cartesian design is particularly convenient as it allows scientist to swap out different kinds of sample, without having to find the matching cap corresponding to the cuvette used. The cuvette colorimeter availability of methods makes the use easy, thus saving in time and making the process of handling of samples more efficient and helps the scientist to concentrate on his work rather than searching for tools.

The quality of the measurements depends on any interference of light path during the use of a spectrophotometer for analyzing a sample. Cuvette caps are optimized to reduce this type of optical interference. This offers a clean path for the light to travel through the sample, thus minimizing the colorimeter cuvette possibility for any discrepancies in measurements. This guarantees that the results obtained are as accurate as possible and is absolutely crucial for scientists who need precise data to make inferences about their work.

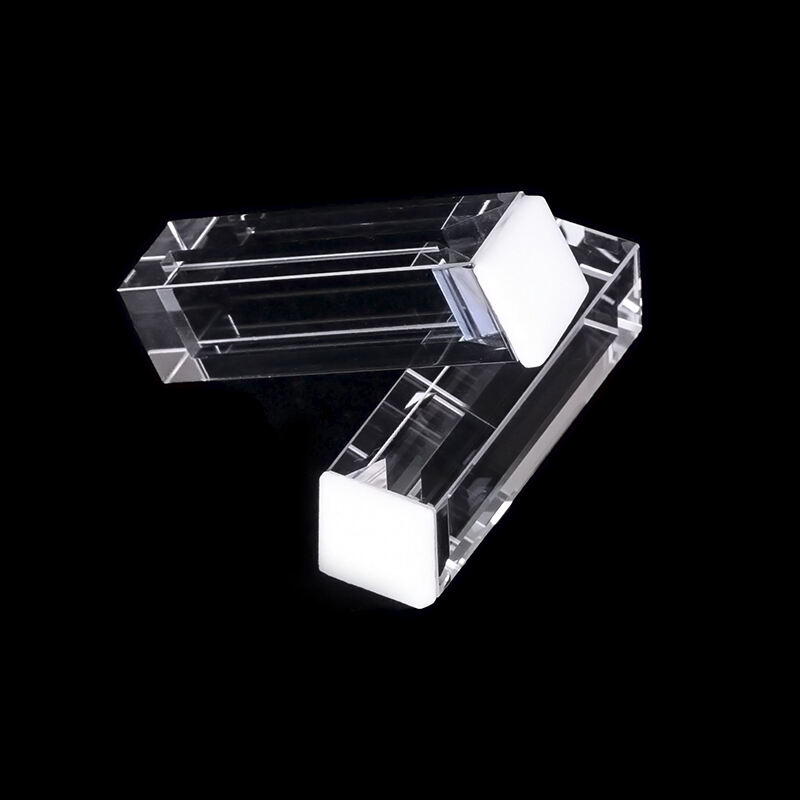

On other end of the line, we have Jinke Optical, which is a professional and leading manufacturer focusing on high quality cuvette cap for the use in scientific laboratories. They reflect mirrors come with strong durable plastic cap for sample protection. Cuvette caps for Jinke Optical help scientists make precise measurements, making them a great tool for scientists. Jinke Optical's cuvette caps have a simple and easy-to-use design, but they are also powerful and high-performance, making them widely used as sample analyzers for spectrophotometers in laboratories.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.