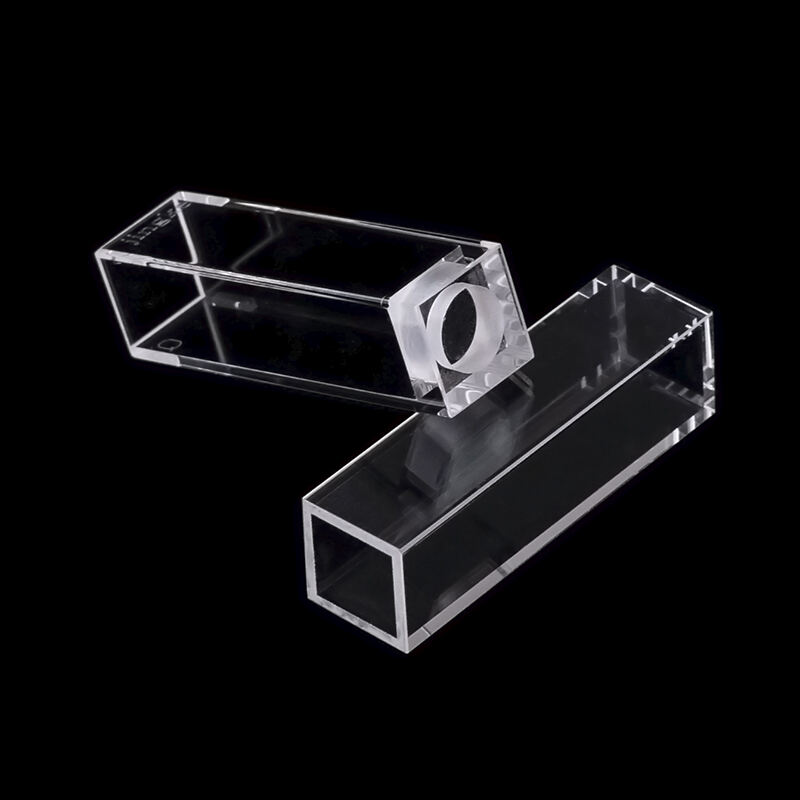

In the laboratory, when scientists do experiments they tend to use a type of instrument known as a spectrophotometer. This allows them to measure how much light is absorbed by a sample. They place a small, clear container called a cuvette inside to hold the sample. This is why cuvettes play an essential role in this process, as these devices allow the light to travel through your sample but keep it protected inside the plastic. But it’s not enough to simply have a cuvette. The orientation of the cuvette can have a significant impact on the accuracy of results from the spectrophotometer.

In the spectrophotometer, one common error committed by the scientist is putting the cuvette in the wrong direction. If the cuvette does not line up perfectly with the light beam, some light can miss the sample entirely. This may led to inaccurate results, which is a serious problem for the experiments here. The right alignment of the cuvette with the beam of light originating from the spectrophotometer is crucial to ensure that you do not make the same mistake. Many Cuvettes have notches or arrows indicating their proper direction. These instructions must be followed carefully in order to guarantee the accuracy and reliability of the measurements.

Genetics rely heavily on DNA measurement, which is an essential aspect of scientific research. The scientists have to know how much DNA there are in their samples so that they can properly compare the results of their experiments. This measurement can be significantly impacted by the orientation in which the cuvette is placed. DNA must be quantified at a wavelength of light. The angle of the round cuvette can resist the extent to which light is absorbed by the sample. Making sure the cuvette is properly aligned can minimize incorrect readings of DNA concentration. Thus, ensuring the cuvette is properly lined up is critical for accurate DNA results from experiments.

Fluorescence spectroscopy is also a major technique that scientists employ to detect the bright light emitted from a sample. In this way, how strong of the light signal is detected can depend on the placement and the direction of the cuvette. Conversely, placing the cuvette too close to the detector can cause the signal to be too intense, which is referred to as saturation. This makes it difficult for scientists to read the signal accurately. To obtain optimal results, researchers need to be incredibly precise with the placement of the cuvette as well as its angle.

Determining the concentration of proteins in a sample is essential in numerous scientific experiments, particularly in biochemistry and molecular biology. The protein quantification are essential for the proper mixtures and for determining how much protein needs to be for a particular experimental setup. The cuvette's facing orientation is a considerable factor in ensuring accurate measurement of protein concentration. It is necessary to position the cuvette properly on the spectrophotometer, and to balance the sample at the appropriate wavelength of light. In the event that the cuvette is not placed properly, or is in the wrong direction, one can get erroneous measures of protein concentration. So scientists must be careful how they set up the cuvette, to ensure they get the correct results in their experiments.

To sum it up: Jinke Optical cuvette direction matters a great deal in spectrophotometry. Scientists have to make sure that the cuvette is rightly aligned with the light beam during each and every one of their experiments. Researchers can be confident in their results as this makes sure that the cuvette is facing the correct way and placed correctly.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.