Have you ever performed a science experiment? Are you one of those people who likes to mix and measure different liquids just to find out what happens? If you said yes to either of these questions, then you are going to love colorimetry! Welcome to Colorimetry, a fun and exciting measurement of the colors of different liquids. One way you might accomplish this is by using a metering tool known as a colorimeter. This device utilizes color to measure the amount of a substance in a liquid. You will also need a special container known as a cuvette to obtain the most accurate and reliable results. Let us explore further what exactly is colorimetry and how does it work!

Colorimetric is a scientific method used for the qualitative and quantitative analysis of certain substances dissolved in a solution, based on the color of the substance. Different materials absorb different colors of light. This means when light hits a liquid, some colors are absorbed by the substance and others can be transmitted. These are known as colors of absorption and they tell us important information about the concentration of the substance in the liquid. We use this well in all niches, like in scientific experiments, health checkups, and implementations.

The colorimeter consists of a beam of a certain color of light shining through a liquid. It then assesses how much of that color is absorbed into the substance in the liquid. Jinke Optical cuvette colorimeter allows us to know how much of the substance exists. Knowing this allows us to process this information and use it to compute or assume a result based on what we have discovered. Knowing how to accurately use a colorimeter will enable you to obtain memorable and useful results for your experiments.

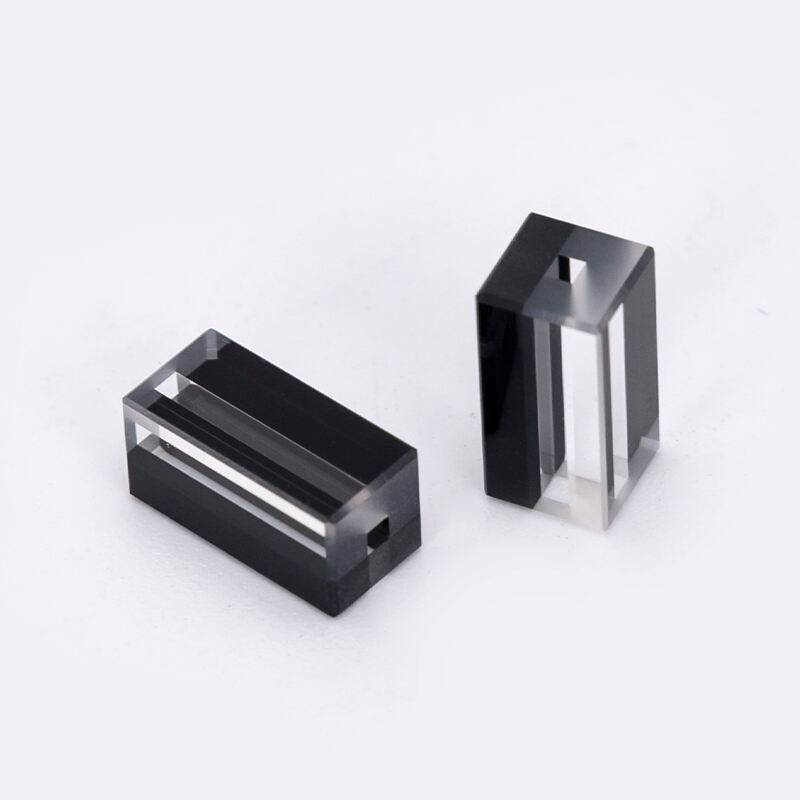

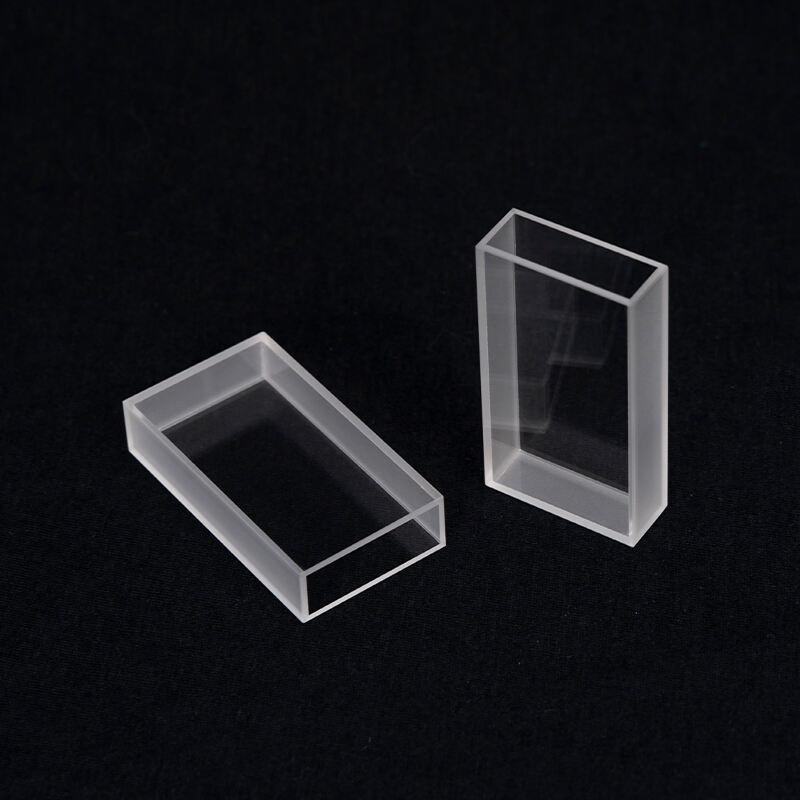

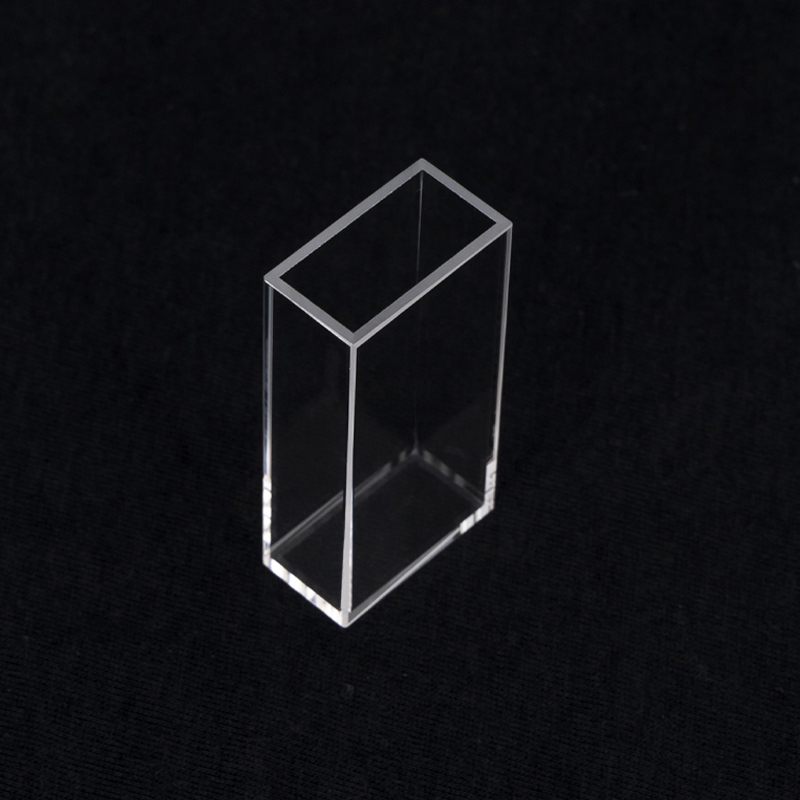

In order to utilize a colorimeter effectively, you first need a cuvette, a specialized container. Its called a cuvette (the container), a small tube or rectangular box that contains the liquid you want to test This is designed to go into the colorimeter as well and allow for the light to pass through the liquid in a consistent manner. Simply choosing the right cuvette can make a big difference in the accuracy of your results. If it is not, you are not going to get optimal information regarding the substance being measured.

Though cuvettes are fabricated from high quality materials such as quartz or glass, which has a very high optical quality. Others may also have special coatings or treatments to improve their functionality, such as anti-reflection coatings or other temperature-control features. Also, using these quality cuvettes will reduce errors due to dust or fingerprints, etc. Most of these Jinke Optical colorimeter cuvette are packaged in sterile, contamination-free environments to prevent contamination.

Glass Cuvettes: These cuvettes have superior optical clarity, allowing the light ray to penetrate and pass without absorbing or scattering it. This can result in increased measurements accuracy. Jinke Optical cuvette spectrophotometer are also capable of withstanding higher temperatures, and are more chemical resistant. But they are delicate, and can easily break if not handled well. They are also sensitive to dirt and need to be cleaned carefully to avoid scratches or other damage that can impair their clarity.

Plastic Cuvettes: Plastic cuvettes are much sturdier than glass cuvettes; hence multiple uses are possible without breakage. Jinke Optical cuvettes are a popular choice as they are also less expensive and available in many different shapes and sizes. But they are prone to scratch and it's also possible that the milky nature of them will influence the measure. Plastic cuvettes will not tolerate heat to the extent that glass cuvettes will, and therefore are not appropriate for every experiment, your specific needs are an important factor to consider.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.