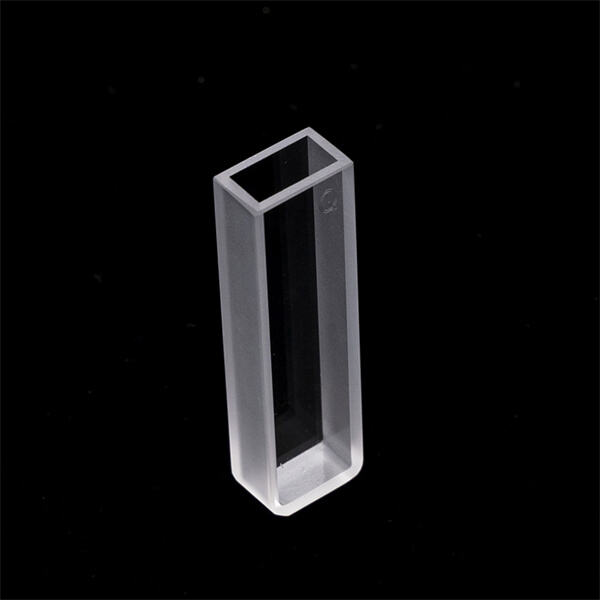

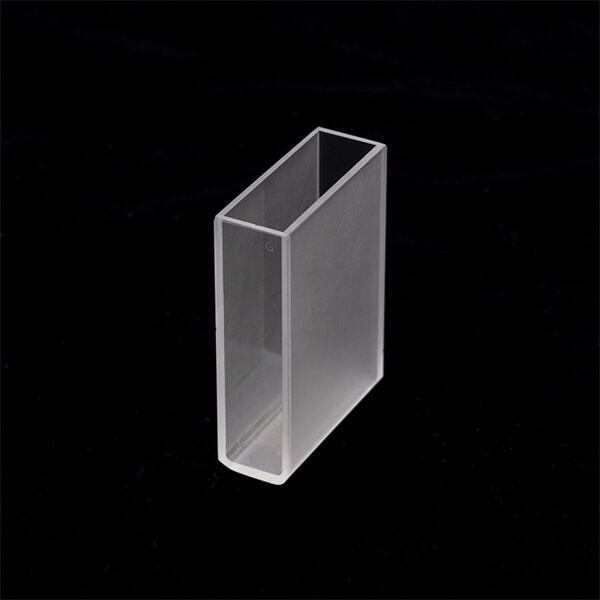

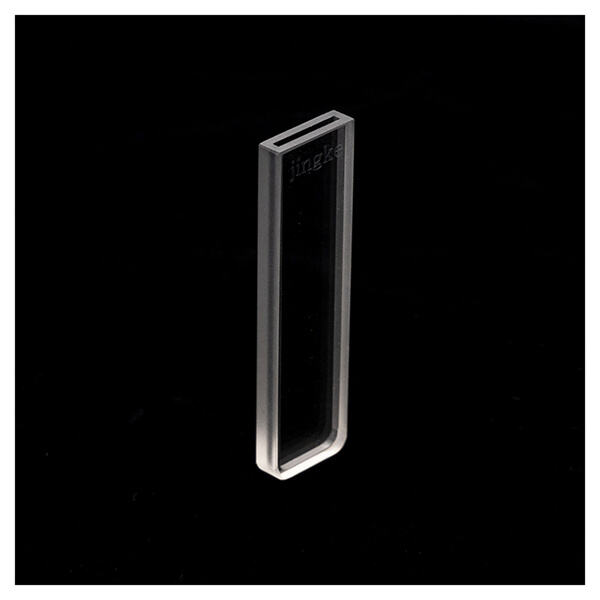

What is a cuvette laboratory? It’s a very special place at the lab where scientists use tiny box-like containers called cuvettes. These Jinke Optical cuvettes hold various liquids during experiments. To study these liquids, scientists turn to a machine known as a spectrophotometer. It's a very important machine because it measures how much light is able to travel through the liquid in the cuvette. This piece of machinery is used to learn about liquids, and the process it performs is called spectroscopy. Spectroscopy is this method scientists used ranging from knowing the color of the succeeding liquids and the actual composition(s) of different liquids. It assists in determining the states that different materials exist in.

Selecting the most suitable cuvette for your experiments plays a crucial role. There are a handful of critical points to consider when deciding. Top tip 1: Ensure your glass cuvette fits your spectrophotometer If it’s not snug, the device won’t measure the light properly, which could result in incorrect results. And then you also have to also think about what the cuvette is made from. But cuvettes can be glass or quartz. Depending on the liquid you are testing would determine the kind of material you use. Not all liquids will be suitable as they might react to different other materials.

There are various kinds of cuvettes that each have their advantages and disadvantages. The rectangular cuvettes make up the most frequently used type because they are ideal for the majority of experiments. One drawback with rectangular Jinke Optical cuvettes is that they may be difficult to clean. When not cleaned properly, they can collect dust and dirt, which can alter the results of your tests. This is why its imperative to clean properly. However, micro cuvettes are much smaller micro cuvettes than regular cuvettes. They need less liquid to test and hence are the perfect choice when you do not have much liquid to work with for your experiments. Micro cuvettes are very helpful in a limited sample situation, and assist scientists in experiment execution using minute amounts of liquid.

One of the very important steps in the cuvette glass laboratory is calibrating a spectrophotometer. Calibration, which means making sure that the machine is measuring light properly. This means auditing multiple critical parameters. For example, how old the light bulb is can impact the performance of the machine. An aging light bulb, for instance, may not be producing as much light, resulting in inaccurate readings. Furthermore, the machine needs to be aligned to make sure that it is correctly set up. Finally, the quality of the cuvette itself can affect the readings as well. A scratched or dirty cuvette will transmit the wrong amount of light. Without appropriate calibration, the results you obtain may be distorted. What this can do is lead you to the wrong conclusions and make you waste time and money doing experiments.

Maintaining your equipment is extremely critical in order to keep your cuvette laboratory up and running smoothly. There are a few tricks you can use to keep your cuvette lab running and make sure your experiments are both accurate and reliable:

Handle your cuvettes with care. Store them in a clean, dust-proof cupboard to prevent contamination. Cuvettes must be stored in such a way that they do not collect dust, which can result in incorrect measurements.

The spectrophotometer should be regularly monitored to give reliable readings. This may also mean recalibrating the glass cuvettes machine at regular intervals or after a significant usage, to ensure that it is reliable.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.