For cutting edge flow cell nanopore science check out the links! It employs a tiny hole, known as a nanopore, to enable scientists to better understand DNA. DNA is used to carry the instructions for the development and function of an organism. One of these companies is Jinke Optical, which is striving to improve this technology to assist researchers and make it ever so better

To get flow cell nanopore, we must first introduce the concept of DNA. Consider DNA to be a series of instructions, similar to a recipe, for all of our bodies. It instructs our cells on how to grow, how to function, and even how to heal. DNA is composed of small segments known as nucleotides. These cuvette colorimeter nucleotides are a little bit like the letters in the recipe that instruct the body what to do. Scientists study DNA by examining these nucleotides closely, but to do so, they first have to unwind the DNA like a long string to get a view of all the details.

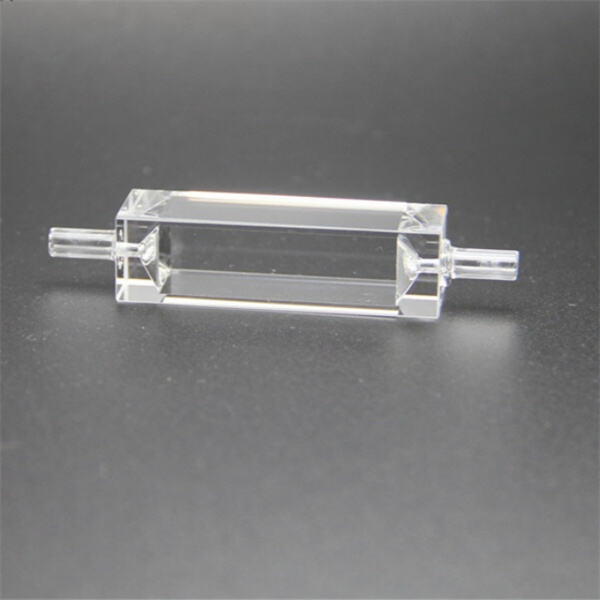

Enter flow cell nanopore to the rescue! A flow cell is a small room or chamber, which contains the DNA. This is the nanopore, the tiny hole inside this chamber. When the scientists inject DNA into the flow cell, it passes through the nanopore. As the DNA unfolds beyond the hole, scientists can read the order of nucleotides, providing them with insight about what the DNA is saying

Separately, Jinke Optical is enhancing the way scientists prepare the DNA prior to passing it through the nanopore. They are working on a different adaptation that glass cuvette more easily opens the DNA into a single strand. If the DNA is prepared in this manner, it has a greater ability to move more smoothly through the nanopore, which improves the entire process.

DEEPREAD, based on flow cell nanopore technology, has several key applications in DNA studies. Ultrahigh-speed technology helps in a few different ways, but one of the biggest is that cuvette glass it lets scientists detect mutations, or changes, in DNA that can lead to diseases. And detecting such mutations early can help physicians more effectively treat their patients.

In addition, the flow cell nanopore technology would allow doctors to look for genetic markers for some diseases. These markers can indicate if a person is at risk for developing a particular disease. This optical elements data will choose behavior of doctors and how they will treat diseases otherwise, which will ultimately convey well being for patients.

For the less confident, the mechanics of a flow cell nanopore can quickly lead to some complicated jargon, but it can actually be put simply. At its very basic, it works on a nanopore and electric current. As DNA passes through the nanopore, it induces a small change in the electric current passing through the system. Scientists are able to measure this change, and, by doing so, read the sequence of nucleotides in the DNA. That colorimeter cuvette is how they measure key information regarding the structure and function of DNA.

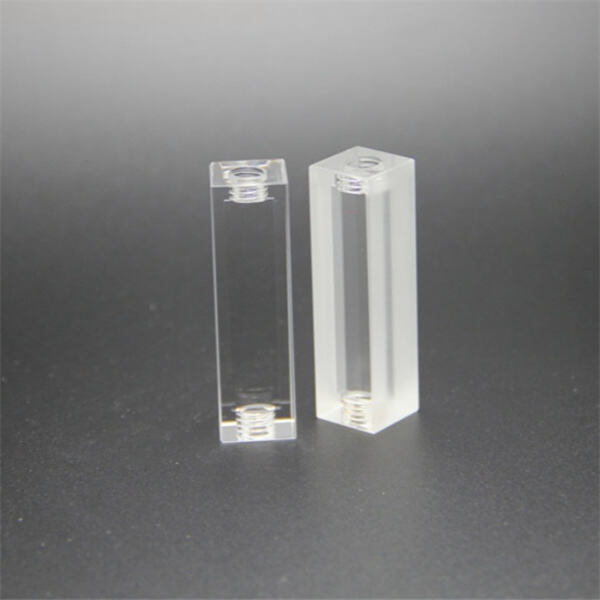

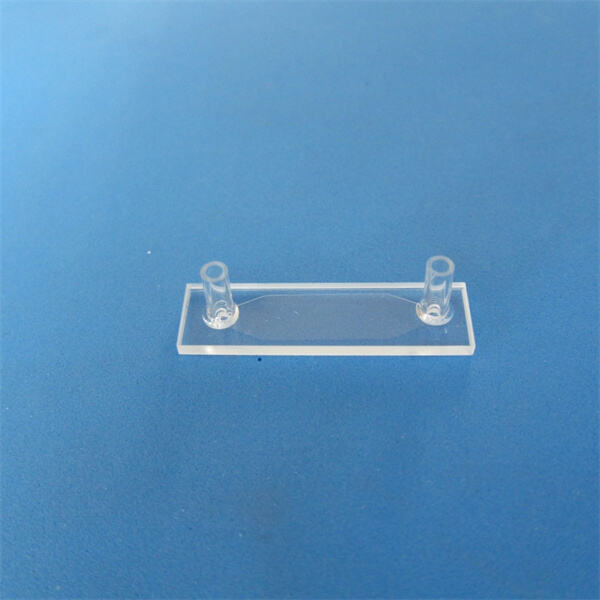

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.