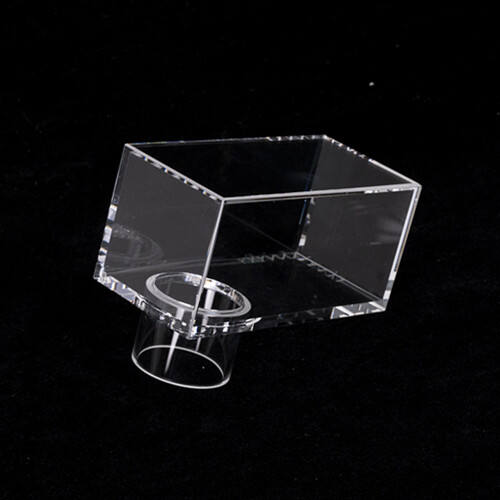

l They use a special device called a Lovibond cuvette. Did you know that this tool is made of glass and is used to measure colors in a number of fields, such as: purified water, food and beverage production, and so on. Various colors are the most important subject for the scientists which they can know with the help of Lovibond cuvettes.

The nice thing about Lovibond cuvettes is that they are always consistent. They are crafted with extreme precision, so each one allows the perfect amount of light to pass through. This means that the scientists can rely on the results they receive. They’re also easy to use, with clear marks and straightforward instructions. Tone: It enables young scientists and even laymen to make accurate measurements with ease. These cuvettes help guarantee that all players read colors the same when they measure.

September 11, 1964Q-992/lif618mzThe Lovibond cuvettes used for reading water color are quite handy for measuring water color as an important water quality monitoring parameter. The color of water can say something powerful about its cleanliness. If the water is clear, it is generally clean and thus potable. But if it looks yellow or brown, there may be bad stuff in it, like dirt or chemicals. Scientists can tell if the water needs to be cleaned by measuring its color using Lovibond cuvettes. It helps ensure that our water remains safe for everyone. It’s an enormous task, but Lovibond cuvettes help smooth some edges of that job.

Lovibond cuvettes are also significant in the preparation of edible and drinkable substances. The color of many food products can be an indication of whether they are still safe to eat. The color can be an indicator of freshness; juice, for instance, should be a certain color

The great thing about Lovibond cuvettes is they do not require any fixing or adjustments. When they are properly constructed they will always yield the right result. This is a significant advantage for scientists, as they can use these tools without anxiety about breaking.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.