Optical cuvettes are specialized devices that scientists or technicians employ for a technique known as spectrophotometry. This critical scientific process one assesses how much if any, light goes through a material. Examples of substances scientists study using this process include DNA, proteins, and medicines. Jinke Optical is a manufacturer commonly used in a wide variety of fields ranging from research, biotechnology, clinical or analytical chemistry, agriculture, etc. Therefore, these cuvettes are suitable for many laboratory experiments.

Optical cuvettes are critical devices in the scientific field. They work for scientists — because the light traverses the sample unobstructed and uniformly. If scientists didn’t use cuvettes, the light would diffuse in various directions and they wouldn’t get accurate measurement readings. This may cause them to make errors in their experiments. This is why one needs quality cuvettes that help scientists to come up with accurate results, and thus it offers cost-effective cuvettes. These disposable cuvettes are constructed from robust materials capable of withstanding harsh laboratory environments, serving as dependable instruments for scientists.

A variety of cuvettes are needed for different experiments. Some require specific cuvettes, while others just need whatever cuvettes you can get your hands on. Our cuvettes have been adapted for various testing from the extensive product line of Jinke Optical Common Cuvette Types: Quartz and Plastic Cuvettes.

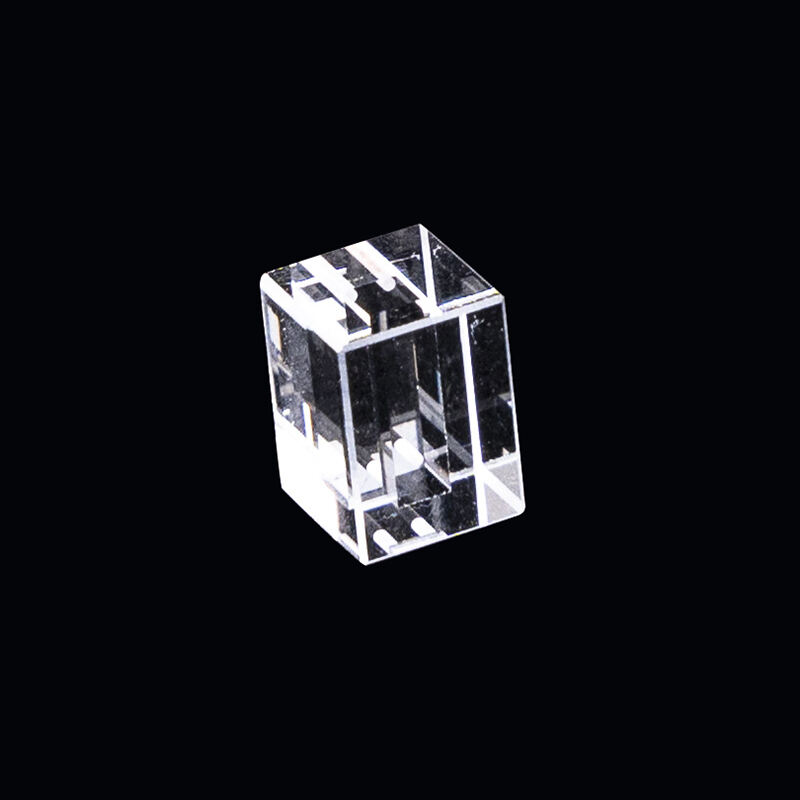

Optical round cuvettes are made of quartz or glass materials. It takes many key steps to create these cuvettes. First, the material gets cut into the right shape for a cuvette. Next, the surface is polished to be smooth and clear. To improve cuvette performance in experiments, sometimes a proprietary coating is applied to the quartz surface. Once they are created, the cuvettes are tested for accuracy and strength before being eligible for laboratory usage. This makes cuvettes with fine materials that do the trick for scientists, providing both transparency and durability to get the right readings.

One big advantage is that they enable scientists to measure the amount of a given substance in a sample without destroying it. It means that they can reuse the same sample for alternate experiments at a later date. Cuvettes also produce reproducible results, aiding scientists in comparing measurements and obtaining meaningful conclusions. Jinke Optical plastic cuvettes are manufactured with extreme accuracy to allow them to hold their preciseness even after many uses.

Fluorescence and absorbance are the two dominant types of measurements in spectroscopy. Fluorescence is a measurement of the amount of light that is emitted when a substance absorbs light of a certain wavelength. This means that the substance fluoresces or emits light when excited. In contrast, absorbance indicates the amount of light absorbed by a substance when light at a particular wavelength passes through it. Scientists can rely on cleaning cuvettes for both types of measurements.

Cleaning optical cuvettes is a necessity; scientists need to keep such devices accurate and functioning properly. If cuvettes are not properly cleaned, dirt and other contamination can worsen over time and ultimately give incorrect readings. They advises scientists to clean cuvettes with distilled water after every usage. They should also gently wipe the cuvettes with a clean cloth in order to get any remaining residue. A mild detergent can be used for especially stubborn stains that refuse to budge. Scratching the cuvettes is also not ideal before using it for measuring the readings as scientist needs to maintain the cleanliness and reliability of experimental readings.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.