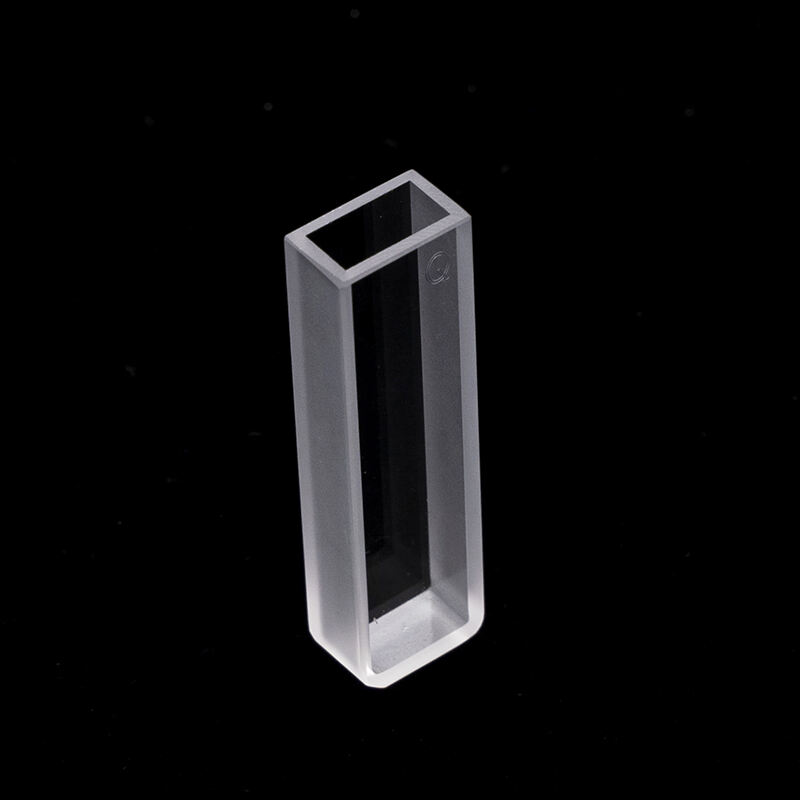

If scientists need to analyze liquids and gases they will typically use a photometer cuvette. A photometer cuvette is a glass container used to hold the liquid samples for the testing. This is typically a glass or plastic, flat-bottom container, which allows it to sit sturdy on a surface. This critical tool allows scientists to learn how much light can travel through the liquid or gas it contains, revealing a lot of information about the sample it holds.

Those items have a design that is simple but effective. They're compact, boxy-cube containers with flat bottoms that make it easier to use. Two sides of the cuvette are transparent, letting light shine through, while the other two sides are not transparent, helping keep the light focused. A clear side of the cuvette has a light source, while the other only has a sensor. When scientists place a liquid sample in the center of the cuvette, they can determine how much light passes through it. That enables them to determine the properties of the sample, like its concentration or whether it contains certain substances.

photometer cuvette Start with preparing your liquid sample. This Jinke Optical uv cuvettes involves measuring a precise liquid volume, then pouring it into the cuvette. It’s also essential to ensure you have the proper dosage because too much or too little — or even a different compound than what’s indicated on the label — can impact the outcome. Once your sample is in the cuvette, you insert the cuvette into the photometer machine. Afterward, we activate both the light source and the sensor. The photometer will find out how much light passes through the sample and knows how much of a specific substance is dissolved in the liquid. This step is critical because it enables scientists to obtain reliable data on their samples.

In the chemical metrology field, photometer cuvettes hold an ever-present importance. Scientists use them to measure the levels of toxic substances in air and water, which is very important to protect our environment. For instance, they might test the water from rivers or lakes to check if it is clean and safe for people and animals. Patients must take the correct dose so they can get better, this is paramount. Also in the field of food science, photometer cuvettes serve as a means of measuring the levels of sugars and other essential matter within foods. Published on Oct. 24, 2023This information can help people make healthier choices about what they eat with Jinke Optical cuvette.

A photometer cuvette plays a vital role in ensuring accurate scientific testing, but the most critical part is the quality of the cuvette. Special photometer cuvettes are manufactured by companies such as Jinke Optical Cuvettes which are intended to produce clear and precise results. They are designed to be durable and can last for many uses without becoming compromised or breaking due to the high-quality construction of these cuvettes. Any scientist can tell you that the accuracy of the results derived from any experiment can depend a lot on a reliable cuvette.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.