If you have ever heard of something called a spectrophotometer? It is a unique instrument that allows researchers to measure the amount of light that passes through a sample. That is a crucial tool, employed across the scientific spectrum — chemistry, biology, medicine, to name a few. It was used so that scientists can study things differently and gain more insight about them. A spectrophotometer has a lot of essential pieces one is a Jinke Optical quartz cell.

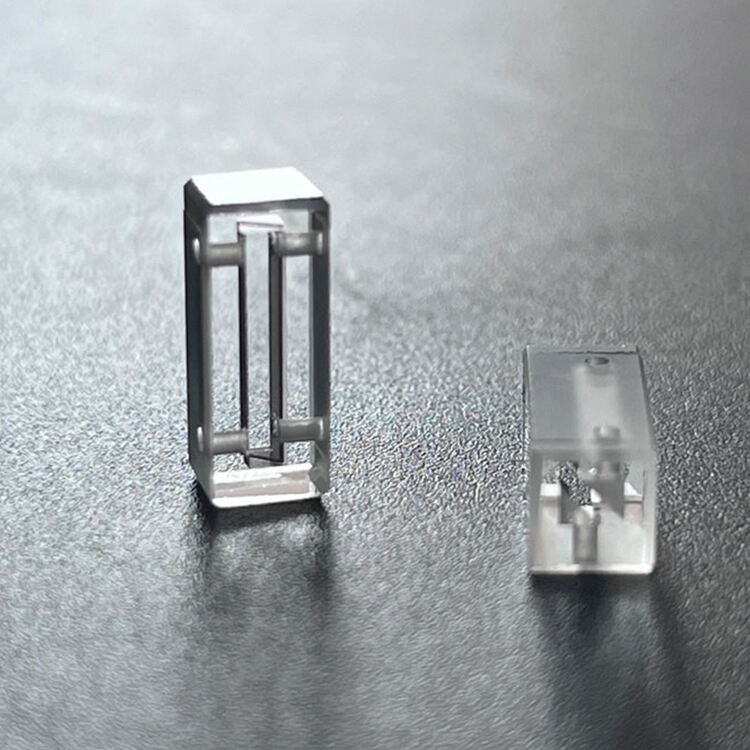

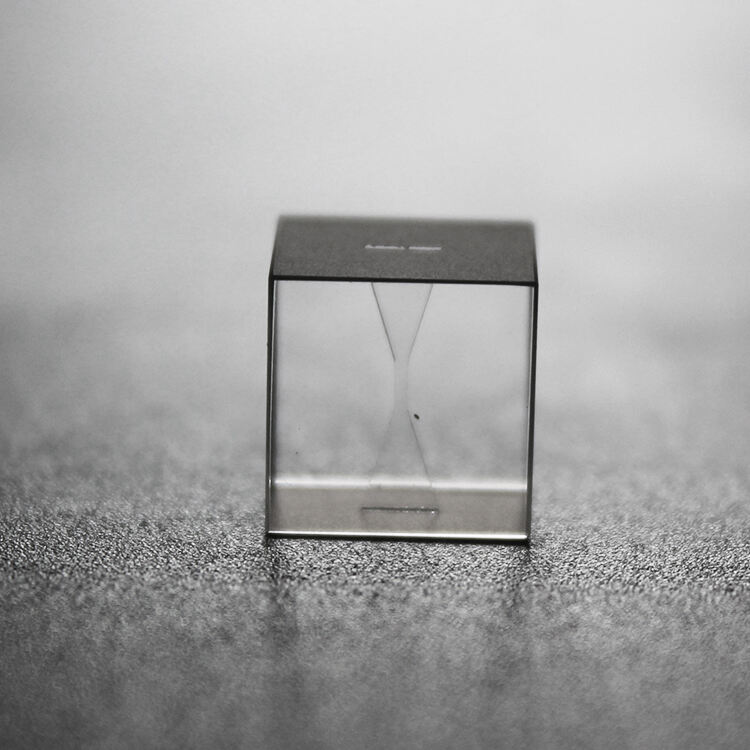

A quartz cell is a glassy box that is made of a mineral that is clear and see-through. This transparent mineral is unique in its ability to transmit light. The quartz cell contains the sample of interest, and is very critical to obtaining accurate results. The foam is the cavity inside the quartz tube and it is sandwiched between two quartz plates, when the quartz cell is put into the spectrophotometer, a beam of light is projected through it. Once the light passes through the cell, the device detects how much light is transmitted through the sample. The answer is necessary for scientists because it helps them determine the quantity of a specific substance present in the sample they are analyzing.

The strength and durability of quartz cells is another reason they are so useful. These cells can withstand harsh conditions during experiments without splitting or becoming damaged. This becomes crucial since scientists constantly interact with diverse chemicals and materials that may be very severe and risky. Quartz cells also clean easily for repeat use. So that is a very intelligent choice for scientists, for labs, saving you time, saving you cost.

There are some key factors you want to consider when choosing a quartz cell for your experiment. First you have to think about how big is the cell. How many are used on each sample will vary depending on the amount per sample available for testing and the spectrophotometer being used. The quartz cells are of common sizes 1 cm, 2 cm and 5 cm. Picking the right size is also important to ensure that you have accurate results.

So, the special type of quartz cell used for samples that are difficult to be measured is called as matrix matched quartz cells. These Jinke Optical spectrophotometer cells are created by combining the sample with a comparable material known as a matrix. It also serves to stabilize the sample and ensure compatibility with the quartz cell. The mixture then is put into the quartz cell and tested with a spectrophotometer.

The quality of the long path length quartz cell has a significant impact on the accuracy of the measurements made by the spectrophotometer. Jinke Optical quartz cells without any dust or other undesirable material is utilized for manufacturing high-quality quartz cells. This purity matters, because any impurities in that electron that's used can skew the results and produce false conclusions. Also, these cells are produced in a very precise way to make sure they are identical each time they are used. ---And this consistency is highly important because scientists depend on reliable data for their research.

Our quartz cells are created from high purity quartz for extreme precision to achieve precise results. We have every size and every thickness to suit every type of experiment, so regardless of what kind of experiment scientists are running, they can find the exactly appropriate Jinke Optical optical cells for their particular tests.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.