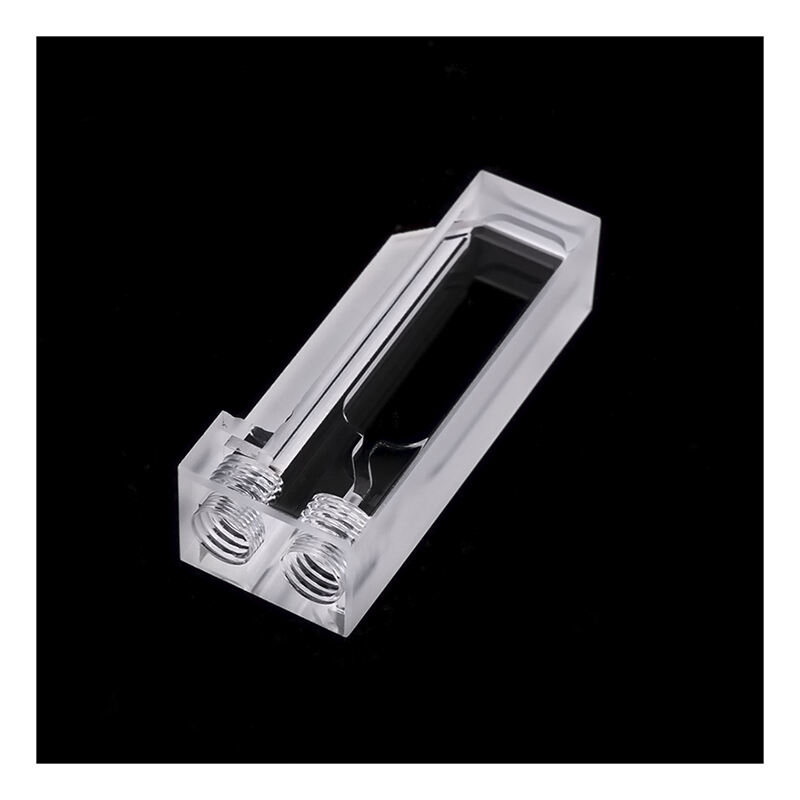

In scientific experiments, cleaning your quartz cuvette is super critical. A quartz cuvette is a container (or small box) that holds samples for testing. Inadequately cleaning your cuvette can alter the reading of your experiments, making them inaccurate. That means you could end up drawing the wrong conclusions from your work. This is why it is critically important to thoroughly clean your quartz cuvette. Here’s a straight-forward way to do so, to ensure that you keep it in good shape and that it works for your future experiments.

This is the first step of cleaning your Quartz Cuvettes is rinse it with water. That means you should hold the cuvette under running water, letting it wash away any of the dirt or leftover material from your previous experiment. Rinsing will remove any small particles that may remain stuck to the inside or even outside of the cuvette. Take your time in this step to ensure all dirt is removed.

It is time to soak your cuvette in a cleaning solution after you rinse it. It is possible to clean with soap and water or dedicate a cleaning solution for quartz cuvettes. If you use the special cleaner, make sure you read the directions on the bottle carefully so you know how long to soak it. Soaking also gets rid of all the stubborn dirt or stains that are stuck on the cuvettes.

After you have done soaking your Optical Cuvettes in the cleaning solution, now you will rinse it again with pure water. This is a crucial step as it will remove any lingering cleaning solution that may remain on the cuvette. Skipping this step could leave some of the cleaning solution behind, which could affect your next experiment. Ensure proper rinsing until you are confident all the cleaning agent is removed.

A common cleaning mistake for the cuvette is not rinsing it properly after cleaning. Residue of cleaning solution might be remained in or outside a cuvette if you don't rinse it properly. This residual cleaner can get into your samples themselves, potentially skewing the accuracy of your results. Always rinse your cuvette thoroughly to make sure no trace of cleaning solution is left.

So make sure to be very gentle when you decide to clean your Jinke Optical quartz cuvette. If it gets scratched, a portion of the film surface will be damaged, making the coating less effective and ruining your results. Always use a soft towel or cloth to prevent scratches while cleaning. A little care can go a long way in keeping your Cuvettes happy.

So neither removing the solutions from the cuvette is good, and as we imply, a specially formulated gentle cleaning solution for cleaning quartz cuvettes. Meter cuvettes are infrared die, which will be damaged with harsh chemicals and all the optical properties may mismatch your experiment. Always read the labels your way and select the a lot of suitable cleaner.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.