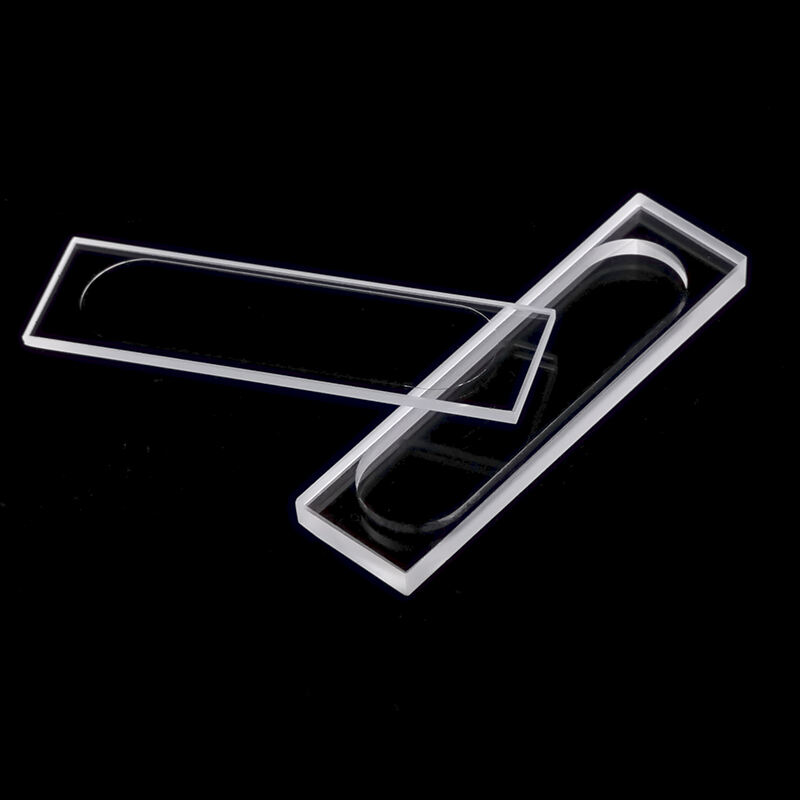

Did you ever wonder how scientists know about very small things, which cannot be seen by our eyes? Though they have some specialized tools at their disposal to observe these tiny objects and one of the more helpful tools in their arsenal is a quartz cuvette. What is a quartz cuvette? A fluorescence cuvette is a small, transparent container made of quartz glass. It is used in labs by scientists as a container for various liquids or gases that they wish to explore and understand. Scientists can then measure light coming through the sample within the cuvette and observe it as it passes through so that they can get a better understanding of what the sample is and what it does. It is fluorescence that scientists find really interesting, which is something they are doing with the quartz cuvettes. Fluorescence occurs when specific molecules in the sample absorb light energy. This energy excites the molecules, making them jump up to a higher energy level. As the molecules settle back down to their baseline, lower-energy state, they emit that excess energy, which they’d absorbed, in the form of light. This light is significant because it is quantifiable, and allows scientists to collect additional information on the sample being studied. Fluorescence allows scientists to learn so much about the materials being worked with.

Fluorescence measurements that scientists perform on quartz cuvettes are crucial to many branches of scientific research. Biologists, who study living things, explore proteins and DNA, the key building blocks of all living organisms, by looking using fluorescence measurements to study their properties. Fluorescence is used by chemists, scientists who study substances and their reactions, to explore various chemicals as well as how they interact with one another. It can measure fluorescence, for example, is also used by material scientists, whose focus is on understanding how different materials respond to exposure to light. For all these applications, fluorescence measured accurately with a fluorescence cuvettes is the foundation of successful research. The scientists also need to be able to trust that their measurements are accurate if they wish to make significant discoveries. These are good tools to apply correctly following some best practices so scientists can get more widely accepted information that can make new research and discoveries exciting in their field.

However, a fluorescence quartz cuvette should be free of defects, breakages, if it is defective it cannot be used for UV spectrophotometer. Also, if the quartz has any problems, it may modify the way light goes through the sample, generating wrong measurements. They also have to keep the quartz cuvette really clean and handle it carefully to prevent defects. It also gives them control on keeping the cuvette in a good condition so that they can perform accurate experiments.

There are several important considerations that scientists should make when selecting a quartz cuvette for their fluorescence experiments. One of those factors is the size and shape of the cuvette for fluorescence measurement. Depending on the size and shape of samples, different optimizations may provide better results. They also need to take into account the optical properties of the cuvette, such as the transmitted signals and fluorescence. These factors can play a major role in determining the accuracy and reliability of the measurements.

Another important property is that the hellma fluorescence cuvettes should be durable and long-lasting. They should ensure that the system is compatible with other tools and equipment that they plan to use in their experiments. It is crucial to use a high-quality quartz cuvette from a reputable company. By making this selection, you may guarantee that the cuvette will perform effectively for the specific experiment you are performing and will yield reliable results.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.