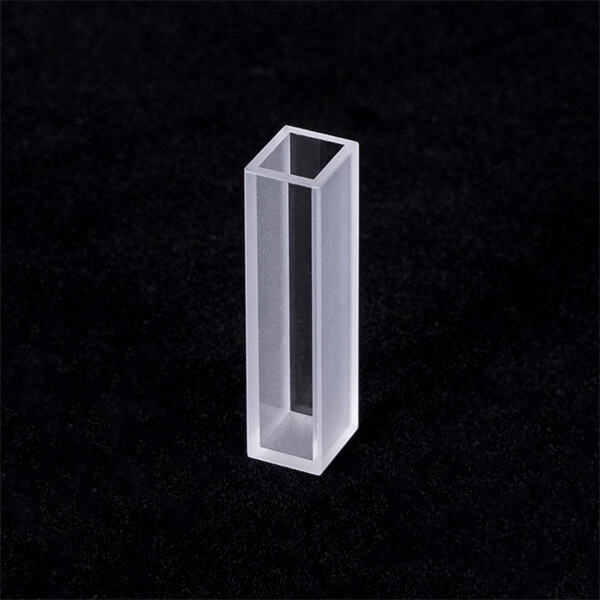

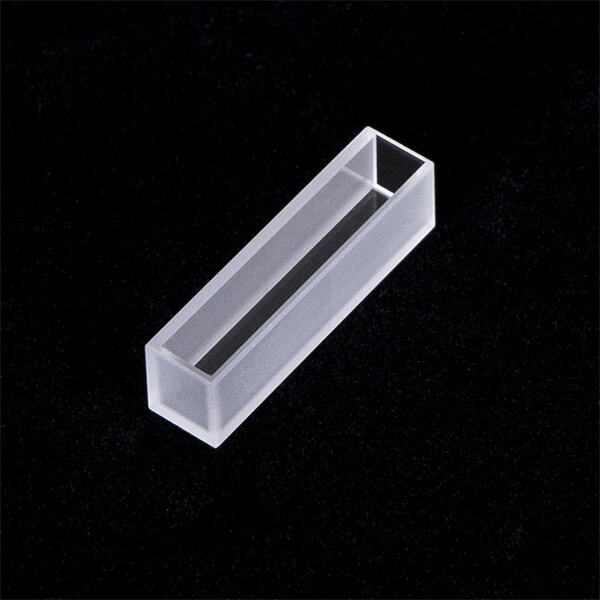

Have you ever wondered how scientists discover what various substances are like? A reaction cuvette is a container made of plastic or glass. Scientists employ it in a process known as spectroscopy. Spectroscopy is a scientific method of analyzing the properties of substances, such as chemicals, by examining the interaction of light with those substances. The reaction cuvette is especially important within that process. It aids scientists in measuring how a material absorbs or passes through various forms of light. The fact that they have access to such data is very useful because this way they can gain considerable knowledge about the substance they are researching.

Being correct is pretty dang important when scientists measure chemicals. Even small errors can lead to major issues in their research. So reaction colorimeter cuvette are critical in experiments. They assist scientists in tightly controlling their experiments. This means they can ensure their measurements are as precise as possible. By making sure the same kind of cuvette is used for every test, they can avoid variances that could otherwise influence their results. Making everything the same helps them find the correct answers. When doing research with sensitive or reactive samples that can change rapidly, this is especially true.

When it comes to measuring absorbance and transmittance, you need to use reaction cuvettes. Absorbance is the amount of light absorbed by a given molecule, at a certain wavelength. This means when light hits the substance, some of that light gets absorbed and does not return after it hits the material. Transmittance, in contrast, describes the amount of light that passes through a material without being absorbed. In other words, it measures the transmission of light through the material and of light on the other side of the material. If scientists can measure these two things, they learn a great deal about what something is made of. Such examples include characterizing unknown substances or tracking the progression of a chemical reaction over time. This allows for their understanding of the alterations that occur within these reactions.

There are different types of reaction plastic cuvette and each type has its own merits and demerits. The most common type of cuvette you will find are glass cuvettes. The connection between them is usually quite strong and is long-lasting, which is probably what makes them suitable for many new experiments. But they can be more expensive than other types and may not be appropriate for use with certain types of chemicals that can shatter them. Plastic cuvettes, on the other hand, are typically less expensive and are more resistant to some chemicals. They react faster and are easier to use. However, plastic cuvettes are typically inferior to glass cuvettes in terms of strength, and plastic cuvettes may also only be suitable for short-term use. Choosing the right cuvette for what you need is very important because each one will measure different results depending on the experiment that you are performing.

In order for your reaction cuvettes to yield optimal results, they must be cleaned and maintained carefully. Rinsing cuvettes with clean water after use, to get rid of any remaining sample, is paramount. This step prevents new samples from being contaminated with old samples, which can cause false results. After rinsing, the cuvette should be left to soak in a cleaning solution for at least 30 mins. This ensures that if any trace of the sample might have been missed, it is now gone, and that the cuvette is clean and ready for the next use. After soaking, rinse the cuvette again with clean water and allow it to air dry completely before putting it back in a clean, dry place. Keep in mind, never use strong chemicals or rough materials to clean your cuvettes, as those can damage them and influence how accurately they are working on future experiments.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.