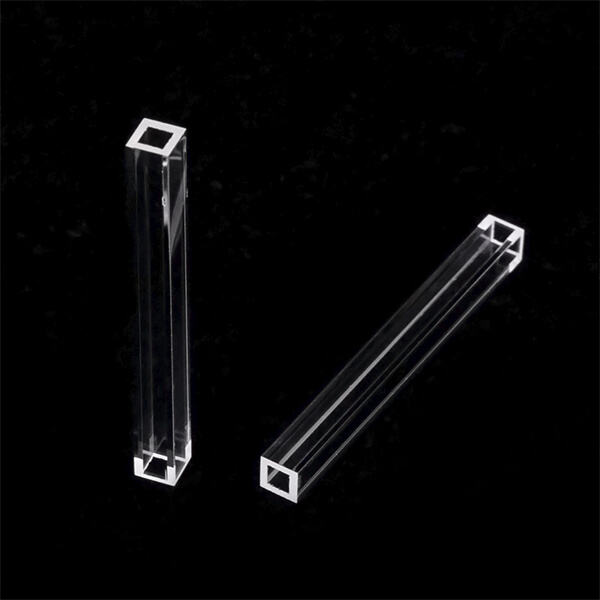

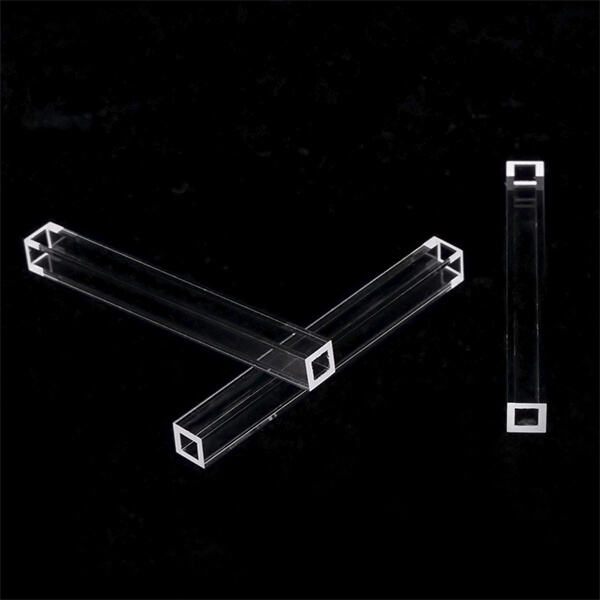

When we observe a rainbow in the sky, we observe many attractive colors like red, orange, yellow, green, blue, indigo and violet. But did you know that scientists can observe even more than just these colors? And in a way scientists, using a special tool called a spectrophotometer, are looking at invisible things, something we do not see with our eyes. This assists them in examining the tiny molecules that compose everything that surrounds us, including the air, water, plants, and even our own bodies. This article discusses spectrophotometer tubes, which are key components for these scientific instruments. A cuvette uv spectrophotometer is a machine that analyzes the colors of various materials. It can also read how much light a substance absorbs or sends back out. In order to do this, scientists place a sample of the substance into a tube known as a spectrophotometer tube. They then pop the tube into the spectrophotometer. The machine passes a light through the tube and measures how much light passes through it. This process provides scientists with more insight into what they are studying, helping them understand more about the properties of that particular substance.

Now that you know what spectrophotometers does, you can understand the importance of maintaining quality tubes. A poorly made tube can cause trouble for scientists. For instance, when a tube has a small crack or is not entirely clear, it can lead experiments to yield different results. This can result in misinterpretation, and that isn’t a good thing for science or our comprehension of the planet. Different experiments also require different types of quartz cuvette for spectrophotometer for them to function effectively and accurately. The type of light that will be used in the experiment is an important thing to consider in choosing a tube. Meaning some tubes are better for specific types of light than others. For instance, some have tubes specifically for ultraviolet light and others work primarily with visible light.

Many different materials can be used to manufacture spectrophotometer cells. It's crucial to select the right material to obtain accurate results. One of the common materials for these tubes is quartz. Quartz is quite helpful for experiments needing ultraviolet light; it permits the light to transmit easily. But quartz is also more delicate than other substances, so it can shatter more readily. That’s why it isn’t always the optimal option for a particular experiment.

Glass is another common material for spectrophotometer cuvette. Glass has a high degree of transparency and strength, making it a common choice in many experiments. And you’ve got to keep the costs down, and it’s less expensive than quartz, too, which is great for scientists.” But glass isn't the best material to use when conducting tests in very high accuracy because glass can reflect light, leading to slight distortions in the results.

Proper care and handling of the quartz cuvette uv spectrophotometer are essential to ensure that scientists receive accurate results. A primary rule is cleanliness of the tubes. Even microscopic particles or dust sitting on the surface of the tube can affect the outcome of an experiment. Keeping tubes clean and accurate is easier with a soft cloth and distilled water.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.