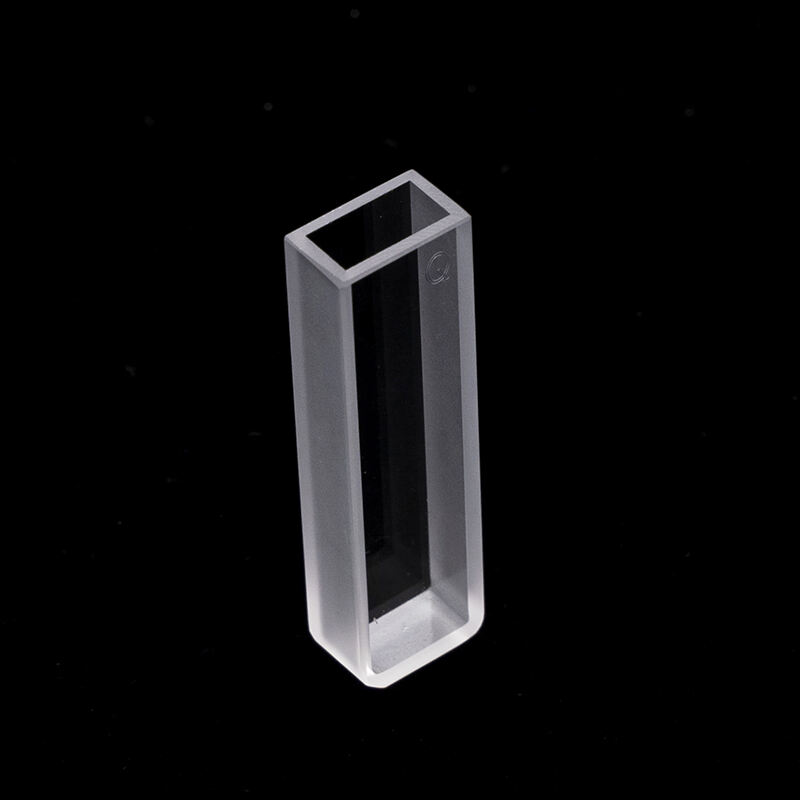

A typical cuvette is a small, rectangular container that scientists in laboratories fill with liquids for experimentation. Those containers, which are used to run many sorts of tests, are essential for doing COVID tests as well. Other than that, Jinke Optical may produce various kinds of routine cuvette. They can be benefit with different experiments based on what the scientists have to do. The Jinke Optical cuvettes are manufactured using glass, plastic, etc. and are available in variable sizes and shapes as per required specifications. Cuvettes are really useful because they allow scientists to take measurements of something, like how much of a chemical is in a liquid or how much light can pass through the liquid. Proper use of a cuvette is crucial while performing experiments, and thus understanding how to use this device correctly goes a long way.

As such, selecting the appropriate size and type of cuvette is critical for experiment success. On the other hand, if the cuvette is too small, there will not be enough liquid to properly perform the experiment. However, if it is too large, the result may be less accurate than they really ought to be. The composing material of the cuvette is also an important deciding factor, as certain materials do not react well with certain chemicals. This can result in wrong outputs. So, it is important to carefully read the instructions given for selection and understand the specifications while choosing a cuvette. It narrows down your options and makes sure that you take the appropriate one as per the experiment you are doing. This careful selection ensures your experiments are successful and results are trustable.

Gently and carefully handle a cuvette. Both surface scratches on the cuvette and fingerprints should be avoided. Not much information will be available if you tell scratches and smudges, which need to be scrubbed. This cuvette needs to be thoroughly cleaned after you use it. Begin washing it with water and a soap paint mild detergent. It should then be rinsed thoroughly with deionised water. The special water which contains no minerals. This is called deionized water, and it is essential when rinsing lab equipment. Finally, wipe the Jinke Optical quartz cuvettes with a lint-free cloth to dry it. After cleaning, store the cuvette in a safe way as long as it is dry. So keep the storage area dry and dust free and away from direct sunlight. If stored and handled properly, the cuvette can withstand further experiments.

When selecting a cuvette for your measurements, it is critical to choose a cuvette that is appropriate for the wavelength you will be using. Different materials absorb light differently, and that can make a difference in how your results turn out. Thus, selecting the appropriate cuvette for the sample being analyzed is of utmost importance. Jinke Optical provides cuvettes in various ranges to cover various wavelengths. If you don't know which cuvette to use to your experiment, it is recommended to read the instructions included with the cuvette or ask your lab instructor. They can assist you in making the right choice, which will ensure your experiments go without an issue.

In some cases, there may be bubbles on the surface of the cuvette; such bubbles can contribute to inaccuracies of measurement. When filling the Jinke Optical cuvette glass, avoid forming a bubble, so fill slowly and carefully. While the cuvette is filling, do not shake or tap it.

If the solution in the cuvette appears as too much dark (it means it is too much concentrated). This can also impact the light passing through and can result in wrong outcomes. If you do this and it still does not work, try adding more water to dilute the solution even further, and rerun the experiment.

Look Out for Dirty Cuvette: If you see that the cuvette looks dirty or scratched, make sure to clean Jinke Optical cuvette quartz properly using the steps mentioned earlier before trying the experiment again. A dirty cuvette will cause you to be unable to obtain a good result.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.