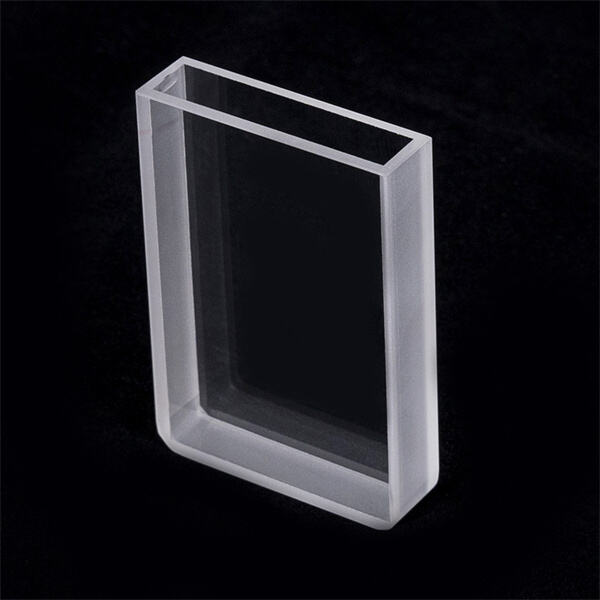

Have you ever heard of a spectrophotometer? It is a fancy word, but it really just means a special tool that scientists use to measure colors and light from different materials. This tool is very popular among scientists because they use it to calculate the amount of light absorbed or reflected by a sample. Well, a sample is just a little bit of something they want to investigate, whether that be a liquid or a solid. Scientists use a type of material to ship to put a small cup like object which directly makes the spectrophotometer work, this small cup is referred to as a cuvette. A cuvette is a specialized glass container that holds the sample that needs to be measured by the spectrophotometer. The glass cuvettes needs to be constructed from the correct material because it determines how the light transmits through it. There is a wide variety of cuvettes, the most commonly used being glass, quartz, and plastic. Each kind of cuvette has its pros and cons, based on what scientists need to do with their measurements.

But quartz cuvettes are harder and can withstand higher temperatures, which makes them practical for some experiments. However, they are more expensive than glass cuvettes, so scientists have to weigh cost when making a decision. Finally, plastic cuvettes, the least expensive and most durable of the three types. They are also really lightweight so easy to carry around. But plastic cuvettes also have problems of their own: they scratch easily and they don’t do well at very high temperatures. The high temperature and pressure resistance is one of the best properties of quartz glass cuvette. So they are extremely reliable in different science experiments. Quartz is also extremely translucent, allowing light to pass through very easily and making it very nice for the purpose of measuring various light wavelengths, especially in the ultraviolet range. But scientists have to be more careful handling quartz cuvettes than glass ones because they (the quartz cuvettes, not the scientists) cost much more, so they don't want to shatter them.

Plastic cuvettes are much cheaper than the other types of cuvette glass and much tougher as well. They also tend to be incredibly lightweight, which makes them easy to use and move from one location to another. Plastic cuvettes are not as clear as glass or quartz, however. That means they can’t be used for measurements at high temperatures. They also can scratch or get cloudy, which can make results less accurate. These are crucial factors for scientists to consider while selecting a cuvette.

Selecting the correct cuvette for a spectrophotometer is a critical task and is determined by a number of factors. When scientists, for example, need to select the type of sample they are analyzing, as well as the wavelength of light they use, the level of accuracy they required, etc. Because of this, glass cuvette are most commonly used for standard day-to-day measurements as they are easy to work with and effective. However, quartz cuvettes are used for more accurate measurements within specific ranges of light, such as ultraviolet light.

If highly accurate results are critical then glass cuvettes may be required as plastic cuvettes are used for quick, low-cost measurements only. There are many kinds of high-quality cuvettes for spectrophotometers they produce, including glass, quartz, and plastic, and Jinke Optical is engaged in making all of them. The materials used to create our cuvettes are of the best quality and are designed to (or will) offer scientists accurate results every time. With sizes, styles, and shapes to accommodate your every need, and a friendly staff of experts ready to assist with finding the proper cuvette for any of your experiments.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.