Jinke Optical is a manufacturer of specialized equipment designed to assist scientific researchers. One of these significant instruments is called a UV-Vis Cell. The uv flow cell observe very small matter (small particles, molecules, etc.) These little things surround us, and studying them informs scientists about how everything operates on the planet, from chemicals to living organisms. They can collect data that is critical for the scientists,_SELECTED from those specialized devices.

UV-Vis Cells are one of the most used instrument devices in chemistry. They allow scientists to probe various attributes of samples. They can, for example, detect the color of a sample, or the amount of light that the sample absorbs. That's why this information is really essential as scientists can learn about the components of a sample and the amount of each component provided in the sample. Knowing what a sample is made of helps scientists troubleshoot, develop new materials, and even create medicines.

How UV-Vis Cells Work ~ The Science Behind Spectrophotometry These cells project a unique type of light through a sample. This is Jinke Optical UV-Vis light, or ultraviolet and visible light. Hitting the sample, some of that light gets absorbed by the sample, and the remainder traverses and gets detected by a special sensor. This process generates a spectrum that acts as a sort of fingerprint for that sample. Just by reading that spectrum, scientists can determine what the sample contains. So it allows them to help identify and understand the things that they are learning about.

UV-Vis Cells are very crucial equipment since they are very responsive. They can be used to identify the presence of minute quantities of a substance in a sample. This skill makes them applicable to a wide range of tests and experiments. Without these tools to ensure accurate detection and analysis of samples, scientists cannot make discoveries to help us understand the world around us.

Scientists also use flow cell cuvette to study various materials. Characterization of materials is the study of the physical and chemical properties of materials. When light hits a material, scientists know how the light interacts with it, but not how the material behaves. UV-Vis Cells for Light Interaction Data: Scientists use UV-Vis Cells to get information for light interaction. This information allows them to determine what type of material they are working with, and how that type of material behaves in different environments, like at different temperatures or pressures. The understanding of materials is the cornerstone of new technology development and improvement of existing ones.

Scientists often face many factors when choosing a UV-Vis Cell for their experiments. First, they consider the kind of sample that they will analyze. This is suitable for most samples, however, some more delicate samples need specific Jinke Optical micro flow cell designed for those materials. Second, they focus on the type of light source will be employed. Different light sources emit light differently, and some UV-Vis Cells are better suited for certain wavelengths of light. And they also think about the size of the sample, and how precise the analysis needs to be. It is important for professionals in the fields like Biotech and Biochemistry to select appropriate UV-Vis Cell as it plays a vital role in producing the optimal results in their experiments.

With recent improvements of UV-Vis Cell technology, researchers now can conduct more accurate and sensitive analysis than ever before. With the introduction of new materials and manufacturing techniques, it has become possible to develop smaller, portable UV–Vis Cells which can be used in other locations than the laboratory. This portability is especially useful to scientists who are required to collect samples in the field. The technique has also evolved with new software and data analysis tools that are being developed, allowing scientists to interpret the data obtained by UV-Vis Cells. It has allowed scientists to perform increasingly sophisticated studies and study how materials behave in varying environments.

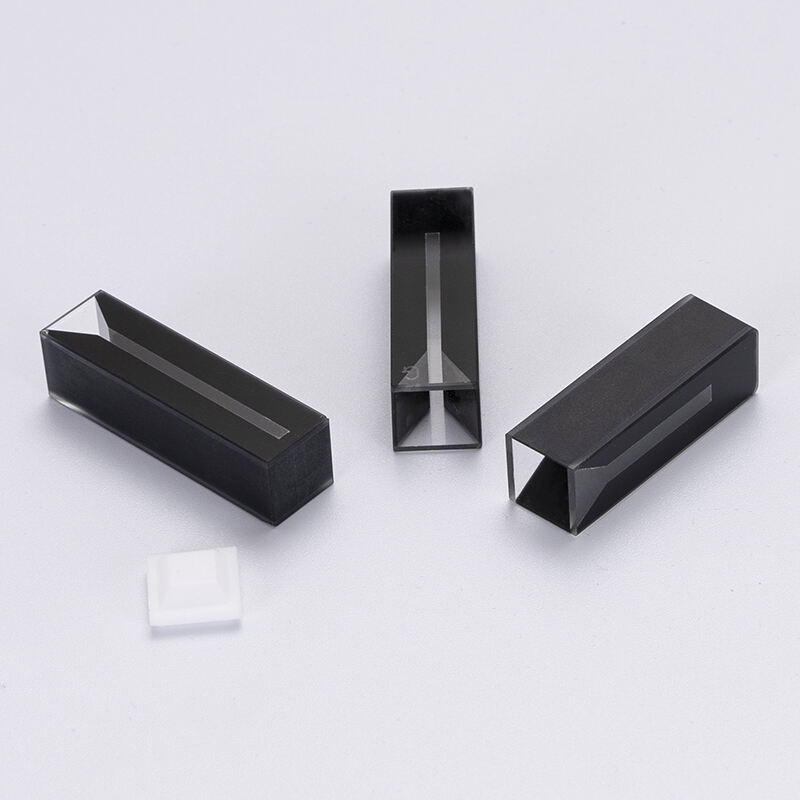

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.