Vapour cells are super neat little boxes scientists use in their experiments. These jars, Jinke Optical which serve an unsuspecting purpose, Jinke Optical vapor cells teach us how tiny little items referred to as atoms make up objects we witness every on a daily basis! Atoms may be incredibly tiny, but they have a huge impact on how things in the world function.

By heating up or cooling down Jinke Optical vapor cells within these cells, scientists can turn up the heat or temperature of the vapour. This way, they can control the behavior of the atoms. This is super crucial because that helps them visualize how atoms respond in different context. They may want to know the difference between heating and cooling atoms, for example. This helps scientists to better understand how atoms behave under different conditions.

Vapour cells are also really important for something known as precision metrology. “How scientists use them to make really precise measurements is a fancy way of saying it. The scientists can use precise measurements of how Jinke Optical vapor cells absorb and emit light to make highly precise measurements of fundamental quantities, such as time and distance.

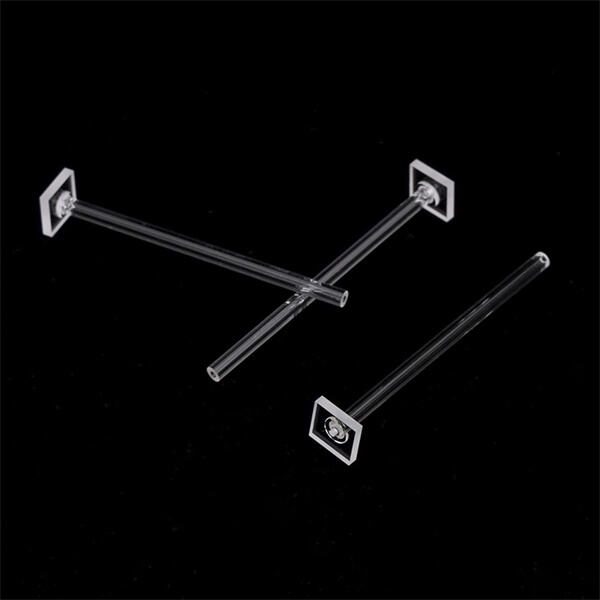

The Jinke Optical quartz cell allow scientists to probe atoms in a wholly new way, which is one of the most exciting features of them. Atoms are so small that no one can see them, but if scientists study them inside vapour cells, they can lead to many interesting findings.

Vapour cells are also a big player in a new field of technology called quantum computing. Researchers are studying how to manipulate the behaviour of atoms in quantum systems, and vapour cells are one tool in making quantum computers a reality. That means Jinke Optical quartz cell could solve problems far more quickly than the computers we use today.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.