An electrochemical flow cell is a special machine that creates electricity from chemicals. It operates by having two liquids flow past one another. And it will collate, these liquids will combine, and will create a chemical reaction. This reaction is what creates the electricity! This electricity can be use for many applications, from turning on a light bulb, charging our phones to powering our computers.

There are many applications of Jinke Optical electrochemical flow cells. In large factories, they help to create the electricity required by machinery that makes the products. We can use them to charge our appliances in our homes, our microwaves and refrigerators. The flowmi are even used in space crafts, providing electricity to vital systems that astronauts count on when they are floating around in space. Thus, electrochemical flow cells can be really beneficial to a wide variety of applications.

Making electricity from renewable energy sources such as sunlight, wind and water is very critical. They are far better for the earth because they are inexhaustible and environmentally friendly. On the contrary, fossil fuels such as coal and oil can be damaging to the planet as will one day run out. That is why electrochemical flow cells are so exciting — they give a renewable energy source.

One major enhancement scientists are working on is miniaturizing and downscaling Jinke Optical electrochemical flow cells so they’re more portable. That means they can be operated in a lot of different locations, including regions without access to conventional power. Getting Power Even if You are not Connected to Power Grid — Powering a Small Village, a Camp, or a Seashore This book can enable many others to have access to electricity.

Electrochemical flow cells are advantageous since they convert chemical potential into electricity. That means they don’t waste as much energy as some other sources of electricity might. Instead, they harness energy from the reaction to generate what we require. Some flow cell cytometry use chemicals that can be recycled, so we don’t deplete materials, we just keep generating current electricity. This means it is a sustainable energy source.

The other aspect of the sustainability of electrochemical flow cells is that they do not generate any pollution. Unlike conventional power sources, they do not burn fossil fuels, which can emit harmful gases that pollute the air. Instead, they chemically manufacture electricity, a more benign process. This is better for our planet and contributes to the freshness and cleanliness of our air.

Electrochemical flow cells are scalable and capable of being used in a variety of applications, and one of the coolest things is their wide range of potential applications. They can supply electricity to buildings in major urban areas, providing power for lights, elevators and computers. They can also assist those in remote locations where there may not be consistent electricity. A small village or a cabin in the woods would have enough space for a huge flow cell nanopore.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

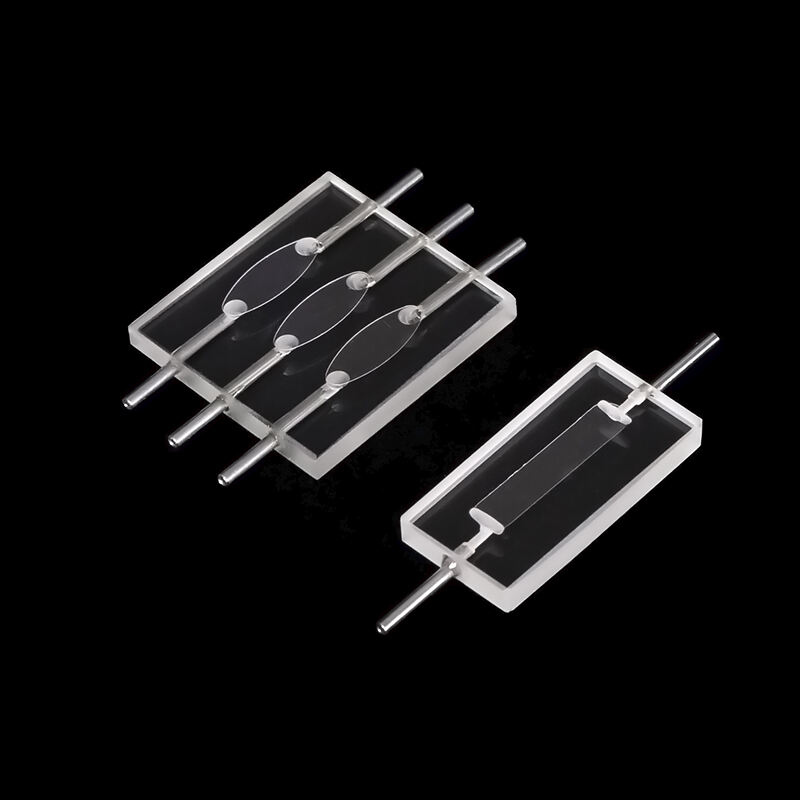

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.