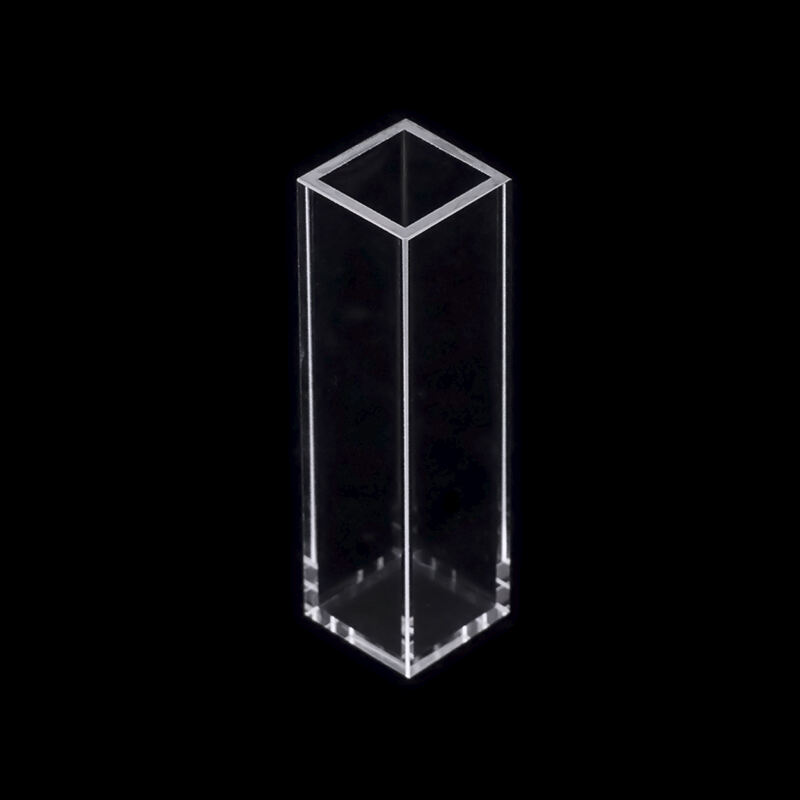

The new technology, called the pH Flow Cell, has been developed by Jinke Optical, and we are very excited to be sharing it with you. This tech is used to measure the pH level of liquids, determining how acidic or basic it may be. If it’s sour like lemon juice, or more basic like soap, we can measure with pH. The pH flow cell is a specialized instrument designed to perform these pH measurements in a continuous manner, such as in liquids. This allows it to provide us real time data on the acidity of liquids which is crucial across multiple industries.

The pH Flow Cell technology has proven to be very helpful and beneficial to once Factory. A tool is used when something is made, such as manufacturing, specifically checking the acidity level of materials during chemical reactions. This is crucial because it ensures the quality and standards in which the final products are manufactured. Food & drink in particular benefit from the quartz flow cell. It lets workers continuously check pH levels to ensure that the products they produce are safe for human consumption.

And this sort of pH Flow Cell would not only apply to food and drinks but also to medicine. This technology allows for the monitoring of pH during the drug formulation processes. Medicine is made in the pharmaceutical industry, which has very strict rules in place to ensure that all medicines are definitely safe to use by people. This ensures the safety and efficacy of the ultimate products which is very important for the health of the patient.

The Jinke Optical pH Flow Cell allows scientists to measure pH in bodies of water including oceans, lakes, and rivers. That helps them understand how healthy these water bodies are. And by knowing the pH levels they can find out if the water is suitable for fish, plants and many animals. The micro flow cell is also able to measure the pH level from soils, which is very vital for farmers. Farmers who test their soil are aware of the pH and can amend the same to make it good for cultivation and healthy plants.

Plant and agriculture industry benefits from pH Flow Cell Determining the pH levels of soil and water is essential for growing healthy and vigorous plants. Scientists have developed this technology that enable farmers to monitor the acidity levels of water and soil to make improvements. If the soil is too acidic, for example, farmers can neutralize it with certain materials, thereby supporting better crop growth.

Additionally, agriculture can also utilize the scanning flow cell to ensure the pH levels in animal feed and drinking water are to spec. This is extremely important because it helps to keep the animals healthy. With just the right pH levels in feed and water, animals will not suffer from problems such as stomach upset or other health issues. Healthy animals are productive and the availability of such animals is essential for food security for all.

Jinke Optical Pioneering this tears diagnostic technology, provides solution from the fluorescence flow cell technology in assisting medical professionals in such important work. Doctors could potentially receive pH signals from the body that help detect diseases earlier. Being able to detect this early on can provide a valuable weapon in the battle against ailments, allowing for treatments sooner and better outcomes for the patient.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.