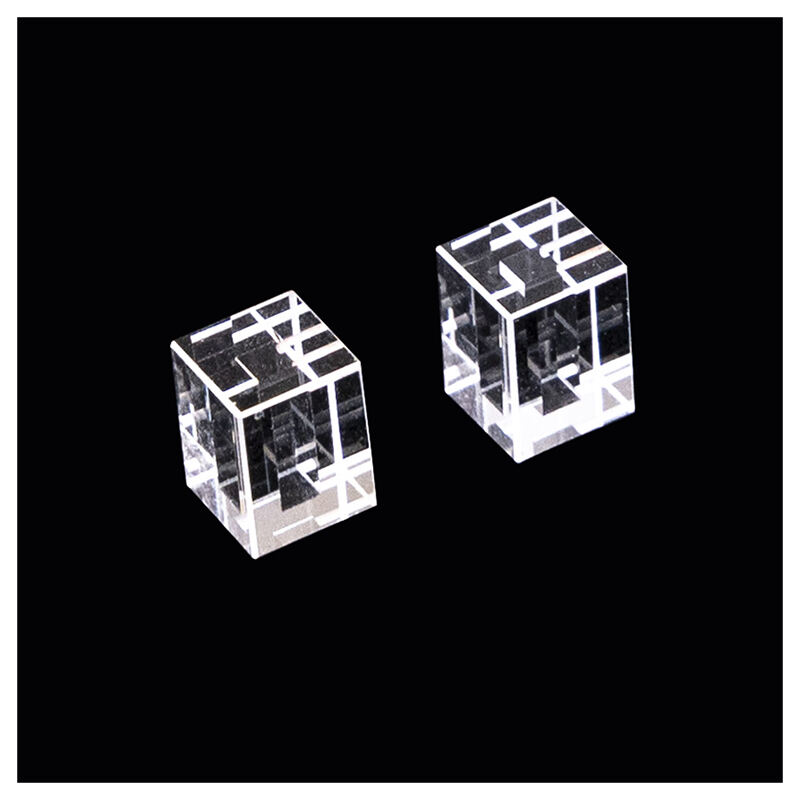

Jinke Optical constructs its own quartz cell — a glass container with a specific type of quartz. This quartz cell is 10mm across: about the thickness of a pencil. (Scientists use this quartz cell in their experiments, measuring various types of liquids.) It is very clear, and, is made from a special, strong, glass. That means it transmits light well. The glass is durable as well, so it can withstand high temperatures without breaking. In particular, the quartz glass used in the 10mm quartz cell is very pure, which means no dirt or other micro-particles are present to reverse the results when measurements are taken by scientists. This means that the quartz cell is an extremely accurate instrument for scientists conducting experiments.

The scientific 10mm quartz cell is here to give scientists the best measurements possible. And it is designed to fit perfectly for several ranges of different types of tests, which enhances its versatility. When the scientists use the quartz cell, the transparent glass allows light to go through without the distortions or problems. This is critical as it promotes the accuracy of the measurements taken. Another great feature is the quartz cells that makes it very easy to use. It can slot into most machines called spectrophotometers, which are instruments used by scientists to sift through samples and gather data. These machines are integral to many scientific experiments.

And there are a number of useful techniques that scientists will use and one such technique is UV-Vis spectroscopy. The method allows them to observe what is known as the absorbance of a sample, which helps characterize how it interacts with light, across a variety of materials. For this method scientists require an appropriate quartz cell that lets UV (ultraviolet) and also visible light through the material without any hindrance. Jinke Optical's 10mm quartz cell is perfect for this, which is made of high-quality transparent glass and is suitable for UV and visible light. With this quartz cell for spectrophotometer, scientists can rely on accurate and consistent results when conducting their tests. This is essential for their research, as they need to trust the measurements.

NOT just an effective 10mm quartz cell design but is designed for steady long-lasting use. This special quartz glass is a very strong material that can withstand both high temperatures and high pressure, making it perfect for a wide range of scientific experiments. Matrix: The shape and size of the quartz cell cuvette are specifically designed for strong durability. Scientists are able to reuse it multiple times, without concern that it will degrade or become broken. Furthermore, the quartz cell is very easy to clean. In this sense, after performing one experiment with it, scientists can just quickly wash it and prepare it for the next experiment. Other labs find this easy to clean and therefore suitable for their use.

Another great thing about the 10mm quartz cell for uv vis from Jinke Optical is that it can be used with various spectrophotometers and other analytical instruments. It also ensures that regardless of the instrument on which the experiment is to be performed, 10mm quartz cell can be accommodated very easily on the instrument. When operational, it will generate precise measurement data crucial to scientific investigations. This flexibility is crucial since scientists frequently need to run different machines based on the experimental setup. The quartz cell is an integral part of their research toolkit, since it is able to work with multiple instruments.

Jinko Optics is committed to providing customers with high-quality products with high cost performance. By optimizing production processes and management processes and reducing production costs, the company can provide more favorable prices while ensuring the excellent performance of products in quality and function. In addition to the excellent quality of the products themselves, the company also pays special attention to after-sales service, providing timely technical support and professional solutions to ensure that problems encountered by customers during use are quickly resolved. This customer-oriented service concept enables Jinko Optics to stand out in the fiercely competitive market and win the trust and praise of a wide range of customers.

With more than 50 years of R&D and manufacturing experience, Jinko Optics has accumulated rich technical and practical knowledge in the field of spectral accessories. For a long time, focusing on the research and development of core products such as cuvettes, flow cells, optical components, and vapor cells has not only improved the company's technical position in the industry, but also enabled the company to quickly respond to various complex application requirements. The accumulation over the years has helped the company to continue to innovate and always be at the forefront of the industry.

Jinko Optics can provide fully customized solutions for the specific needs of different industries and customers. Whether it is drawings and samples provided by customers or personalized needs for special application scenarios, Jinko Optics can accurately design and produce optical components that meet the requirements. This flexible customization capability is particularly suitable for the precise needs of scientific research institutions, laboratories and specific industries. In addition, the company's rapid response to market changes and customer needs can ensure that customers always get the latest and most suitable technical support and products.

As the drafting unit of the national standard for cuvettes, Jinko Optics has very high standards for product quality. Every cuvette and optical component produced by the company follows the ISO9001:2016 standard, strictly controls every link in the production process, from the selection of raw materials to the factory inspection of finished products, to ensure that every product meets high quality requirements. In addition, it has 6 invention patents and 16 utility model patents, reflecting the company's continued investment in technological innovation and process optimization, so that the products not only have excellent performance, but also have unique market competitiveness.